Aluminum and plastic separating equipment adopts the advanced dry type physical separation method, which can help you get aluminum and plastic of 99% separation rate from aluminum composite materials.

Working process of aluminum and plastic separating equipment:

1. Use crusher to crush aluminum plastic composite materials into particles below 4mm.

2. Grinding mill will grind these small particles into 24 mesh powder

3. Control the size of powder by using an eddy-vibrating screen - Bigger powder will be sent back to grinding mill for further grinding.

4. Taking advantage of different conductivity of metals and non-metals, electrostatic separator will separate aluminum from plastic with 99% separation rate.

5. During working process, dust dust removal system and cyclone dust removal system will collect the dust closely to protect the clean of working environment.

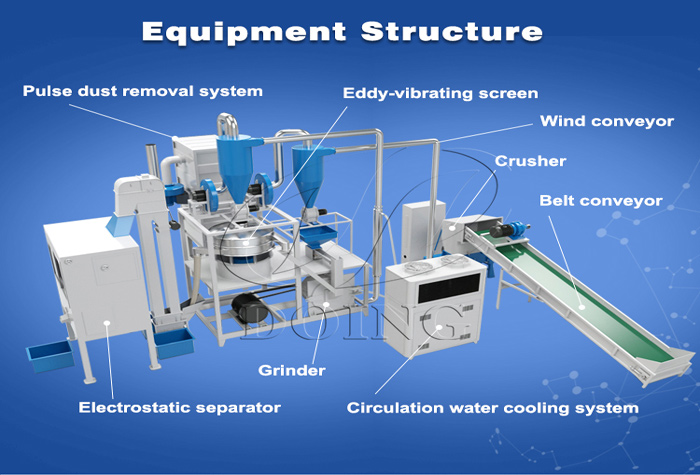

Configuration of aluminum and plastic separating equipment:

Aluminum and plastic separating equipment structure

Aluminum and plastic separating equipment structure

The general configuration includes a crusher, grinding mill, eddy-vibrating screen, electrostatic separator and dust removal system. But there is a small different in grinding mill, which has blade type and disk type to process aluminum composite panels, aluminum foils and medical blister packs. Besides, due to the properties of these materials are different, in order to avoid the plastic get melting at high temperatures during machine running, aluminum and plastic separating equipment needs to be equipped with water cooling system or wind cooling system.

Parameter of aluminum and plastic separating equipment:

| Capacity (Kg/h) | Overall Dimension | Power (Kw) | Weight (Kg) | Recovery Rate |

| 200-300kg/h | 8500*4500*4200mm | 94kw | 6800kg | ≥99% |

| 300-400kg/h | 9500*5000*4200mm | 135kw | 7600kg | |

| 500-600kg/h | 11500*6500*4200mm | 316kw | 12600kg | |

| 800-1000kg/h | 16000*9000*4200mm | 483kw | 13500kg |

Advantages of aluminum and plastic separating equipment:

1. Dry type physical separation method, without burning, chemical solution, smoke, waste water emissions, truly green separation, it won't cause any secondary pollution;

2. Low cost, high working efficiency and high separation rate of 99%;

3. High degree of automation, saving labor - just one or two person is enough for operating machine;

4.Use water cooling and wind cooling system, high grinding efficiency and recovery rate.

Project case of aluminum and plastic separating equipment:

If you are interested in aluminum and plastic separating equipment, welcome to contact with our Doing company, our professional engineer and sales manager will give you difference configuration about the machine. Feel free to contact!

Leave Message

Please kindly leave your requirements in detail, or contact us via +86 15037138562. Our professional sales manager will contact you within 24 hours. Your contact information will be protected.

- QWhat machine do you want to learn about?

- Solar Panel Recycling Machine

- Lithium Battery Recycling Machine

- E-waste PCB Recycling Machine

- Copper Wire Recycling Machine

- Carbonization Pyrolysis Machine

- Radiator Recycling Machine

- Aluminum Plastic Recycling Machine

- Other:

- QWhat raw material do you want to process?

- Bamboo

- Wood

- Sawdust

- Coconut shell

- Palm Kernel Shell

- Wood Chips

- Not decided yet

- Other:

- QMachine processing capacity (tons of feedstock)

- Other:

- Not decided yet

- QWhat final product do you mainly want to obtain? For what applications?