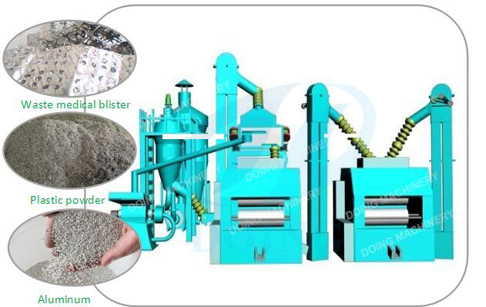

Aluminum plastic separation machine

Workpshop of aluminum plastic separation machine

1.With the aluminum plastic separation machine , the aluminum and plastic can be completely separated for comprehensive utilization and to achieve a higher economic benefit and without dust and secondary pollution.

2. The aluminum and plastic separation and recycling can be completed under multicomputer controlled one time batch-feeding for crushing and automotive conveying, sound insulation and technology and cooling system.

3. Little noise, large output, innovative features. It can maintain the quality of the original aluminum besides recycle plastic. It can generate greater economic benefits for you.

4. It adopts high voltage electrostatic separation technology, higher metal recoveries, metal recycling rate of 98%.

5. This device also uses a triple dust device developed by our company, this dust removal device is composed of three dust collector: Cyclone dust, dust bag and air purifiers dust, can effectively solve the problem of dust pollution

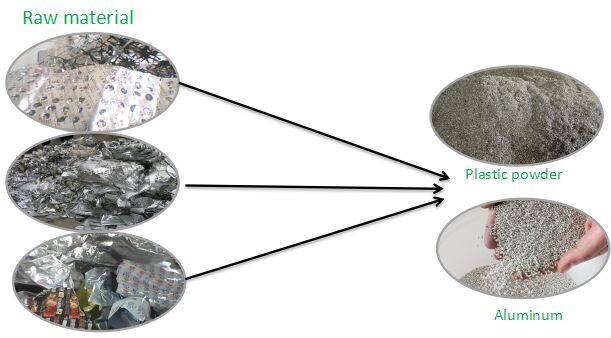

Raw materials of aluminum plastic separation machine

Aluminum composite panels ,aluminum composite pipes ,medical blister ,aluminum plastic boards,aluminum foil ,food packages ,wahaha caps ,toothpaste tube ,bottle caps。

Aluminum plastic separation machine raw material

Technical Data of aluminum plastic separation machine

| Model | Voltage | Power | Capacity | Dimension | Weight |

| DYLS-400 | 380V | 22.45 kw | 150-200kg/H | 2700*1900*2300(mm) | 1200kg |

| DYLS-600 | 380V | 36 kw | 300-400kg/H | 3500*1900*2700(mm) | 3000kg |

| DYLS-800 | 380V | 75 kw | 500-600kg/H | 5500*4500*3300(mm) | 8000k |

Leave Message

Please kindly leave your requirements in detail, or contact us via +86 15037138562. Our professional sales manager will contact you within 24 hours. Your contact information will be protected.

- QWhat machine do you want to learn about?

- Solar Panel Recycling Machine

- Lithium Battery Recycling Machine

- E-waste PCB Recycling Machine

- Copper Wire Recycling Machine

- Carbonization Pyrolysis Machine

- Radiator Recycling Machine

- Aluminum Plastic Recycling Machine

- Other:

- QWhat raw material do you want to process?

- Bamboo

- Wood

- Sawdust

- Coconut shell

- Palm Kernel Shell

- Wood Chips

- Not decided yet

- Other:

- QMachine processing capacity (tons of feedstock)

- Other:

- Not decided yet

- QWhat final product do you mainly want to obtain? For what applications?