Brief introduction of aluminum plate recycling machine

Aluminum plate recycling machine

1.This aluminum plate recycling machine can be completely separated aluminum and plastic, and reach comprehensive purpose, having a higher economic efficiency.No dust, no secondary pollution.

2.The aluminum plate recycling machine is equiped with the combination of multi-machines.Once you feed the raw materials,the machines will automatically process the materials,together with the automatic transmission, sound technology, cooling system,etc;achieve the separation of metal and plastic recycling.

3.The separator rate and the purity is very high,the separator rate can reached 98%,It can generate greater economic benefits for you.

4.Dust removal device is composed of three dust collector : cyclone dust, dust bag and air purifiers dust, can effectively solve the problem of dust pollution.

5. Small power and less power consumption.

Raw material of aluminum plate recycling machine

The aluminum plate recycling machine is apply to all kinds of aluminum plastic composite materials, such as aluminum plastic composite panels, pipes, packages, medical blister, etc.

Working principle of aluminum plate recycling machine

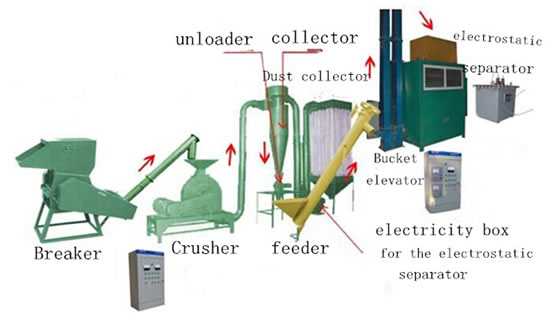

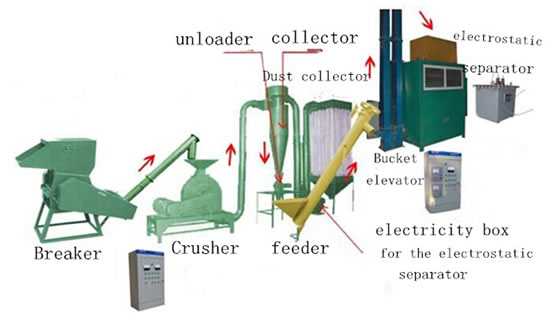

Please check the general process as below:

Working Principle of aluminum plate recycling machine

Crusher→pulverizer→ classifier →separater

Through the secondary mechanical pieces, and make metal and nonmetal mixed powder, again by the air separation technology, or electrostatic separation technology, the metal and nonmetal powder can be completely separated and collected. Dust caused in the production process can be used carbon adsorption removal or closed ring room, dust, or simple bag dust removal, the whole process in a production line to realize, fully enclosed operation,the production of won't produce any pollution. Recovery of metal and fibre glass all can be used again.

Aluminum plate recycling machine

2.The aluminum plate recycling machine is equiped with the combination of multi-machines.Once you feed the raw materials,the machines will automatically process the materials,together with the automatic transmission, sound technology, cooling system,etc;achieve the separation of metal and plastic recycling.

3.The separator rate and the purity is very high,the separator rate can reached 98%,It can generate greater economic benefits for you.

4.Dust removal device is composed of three dust collector : cyclone dust, dust bag and air purifiers dust, can effectively solve the problem of dust pollution.

5. Small power and less power consumption.

Raw material of aluminum plate recycling machine

The aluminum plate recycling machine is apply to all kinds of aluminum plastic composite materials, such as aluminum plastic composite panels, pipes, packages, medical blister, etc.

Raw material of aluminum plate recycling machine

Working principle of aluminum plate recycling machine

Please check the general process as below:

Working Principle of aluminum plate recycling machine

Through the secondary mechanical pieces, and make metal and nonmetal mixed powder, again by the air separation technology, or electrostatic separation technology, the metal and nonmetal powder can be completely separated and collected. Dust caused in the production process can be used carbon adsorption removal or closed ring room, dust, or simple bag dust removal, the whole process in a production line to realize, fully enclosed operation,the production of won't produce any pollution. Recovery of metal and fibre glass all can be used again.

Leave Message

Please kindly leave your requirements in detail, or contact us via +86 15037138562. Our professional sales manager will contact you within 24 hours. Your contact information will be protected.

- QWhat machine do you want to learn about?

- Solar Panel Recycling Machine

- Lithium Battery Recycling Machine

- E-waste PCB Recycling Machine

- Copper Wire Recycling Machine

- Carbonization Pyrolysis Machine

- Radiator Recycling Machine

- Aluminum Plastic Recycling Machine

- Other:

- QWhat raw material do you want to process?

- Bamboo

- Wood

- Sawdust

- Coconut shell

- Palm Kernel Shell

- Wood Chips

- Not decided yet

- Other:

- QMachine processing capacity (tons of feedstock)

- Other:

- Not decided yet

- QWhat final product do you mainly want to obtain? For what applications?