Aluminum separation machine brief introduction

Aluminum separation machine

Aluminum separation machine

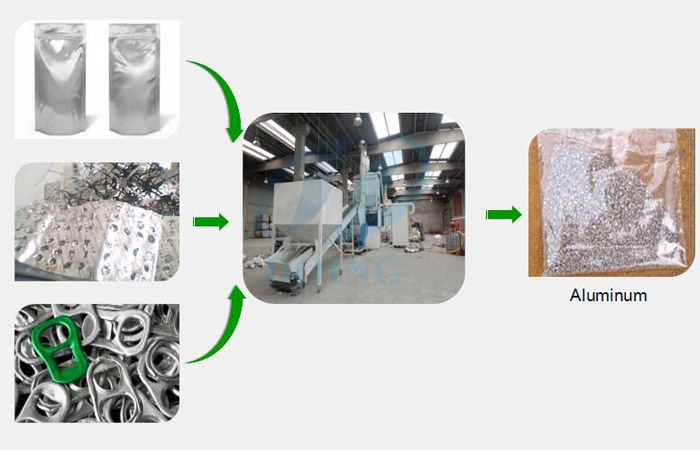

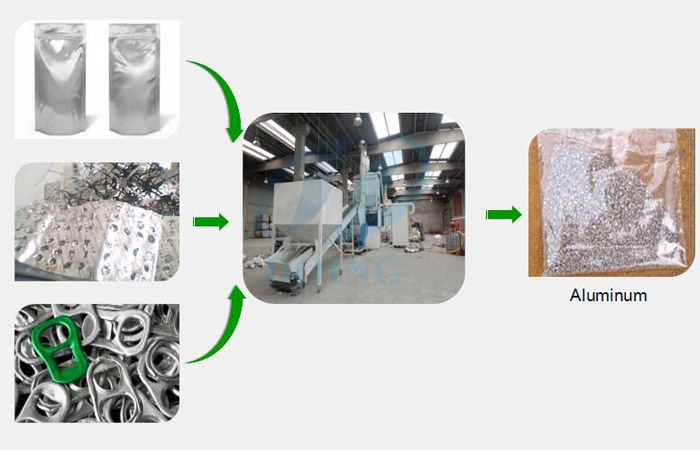

Aluminum separating machine Application to this raw material

Aluminum separation machine

The Aluminum separation machine can be used for recycling all kinds of waste toothpaste tube, medical blister, circuit boards, computer board, TV board, aluminum-plastic plate, copper board, printed circuit boards etc. the metal recovery rate is 99%.

Our waste toothpaste tube recycling machine working principle is: Firstly the crusher processing the aluminum plastic plate into 0.5cm pieces, then the milling machine mills the material into powder, through circular vibaration screen, the powder in suitable size will be delivered to the electrostatic separator. the machine can separate the aluminum and plastic in 99.9% rate. The whole process can be realized in one production line, fully closed operation ensures not creating any pollution.

Aluminum separation machine Performance Characteristics

Our waste toothpaste tube recycling machine working principle is: Firstly the crusher processing the aluminum plastic plate into 0.5cm pieces, then the milling machine mills the material into powder, through circular vibaration screen, the powder in suitable size will be delivered to the electrostatic separator. the machine can separate the aluminum and plastic in 99.9% rate. The whole process can be realized in one production line, fully closed operation ensures not creating any pollution.

Aluminum separation machine Performance Characteristics

Aluminum separation machine

Our aluminum separating machine is equipped with water-cooling system. After long-time work, the temperature of the grinder will still be in normal to avoid plastic melting. Comparing to the normal type, our all-in-one grinder requires less room and has higher efficiency.

Because of the highly automation the whole line requires 2 workers at most.

Aluminum separating machine Application

Because of the highly automation the whole line requires 2 workers at most.

Aluminum separating machine Application

Aluminum separating machine Application to this raw material

Aluminum separating machine is the popular machine to recycling aluminum and plastic from waste ,such as aluminum composite panel,aluminum composite pipe ,aluminum plastic board ,waste medical blister,and others .it adopts an advanced technology that makes raw material to be the mixture of metal and plastic by crushing and pulverizing ,then separates metal from plastic by high voltage electrostatic separator .in this methods ,the metal separating rate is high ,and there is no pollution in the whole production line .

Aluminum separation machine flow chart

Aluminum separating machine Technical data

Aluminum separating machine Technical data

| Model | Voltage | Power | Capacity | Dimension | Weight |

| DYTM-400 | 380V | 22.45 kw | 150-200kg/H | 2700*1900*2300(mm) | 1200kg |

| DYTM-600 | 380V | 36 kw | 300-400kg/H | 3500*1900*2700(mm) | 3000kg |

| DYTM-800 | 380V | 75 kw | 500-600kg/H | 5500*4500*3300(mm) | 8000k |

Leave Message

Please kindly leave your requirements in detail, or contact us via +86 15037138562. Our professional sales manager will contact you within 24 hours. Your contact information will be protected.

- QWhat machine do you want to learn about?

- Solar Panel Recycling Machine

- Lithium Battery Recycling Machine

- E-waste PCB Recycling Machine

- Copper Wire Recycling Machine

- Carbonization Pyrolysis Machine

- Radiator Recycling Machine

- Aluminum Plastic Recycling Machine

- Other:

- QWhat raw material do you want to process?

- Bamboo

- Wood

- Sawdust

- Coconut shell

- Palm Kernel Shell

- Wood Chips

- Not decided yet

- Other:

- QMachine processing capacity (tons of feedstock)

- Other:

- Not decided yet

- QWhat final product do you mainly want to obtain? For what applications?