Cable recycling separator machine's description

The cable recycling separator machine, also known as the scrap electric wire and cable recycling equipment, copper wire separator, aluminium wire separator or electric wire separator.

This cable recycling separator machine is designed to recycle waste electric wire, copper wire, aluminium wire, metallic composite wires, and sheathed lines, contributing to save resources and environmental protection.

Cable recycling separator machine

Cable recycling separator machine

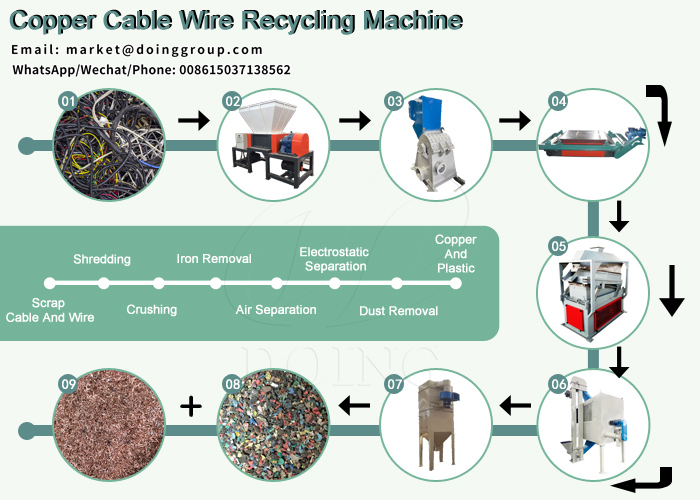

Cable recycling separator machine's working process

The cable recycling separator machine adopts the dry physical method to recycle waste wires and cables. Through the process of crude shredding, fine crushing, gravity separation and vibration separation, pure plastics and metals can be obtained.

The detail working process as fellows: Once the raw material is fed into the cable recycling separator, the waste cable is shredding and crushing into granules. In this stage, copper and plastic are remain mixed. Subsequently, the granules are directed to a vibrating device for further separation. Through a combination of wind blowing and vibration, the copper and plastic are effectively segregated. As a result, pure copper is obtained from one side, while pure plastic is obtained from the other side. Then we collect the separated pure copper and plastic.

Due to the different types of raw materials and processing capabilities, the configurations are also different. The full-line copper wire recycling machine is composed of a double-shaft shredder, a knife crusher, an air separator, a double-layer iron remover, a line-vibrating screen and an electrostatic separator, which can process about all kinds of wires with high efficiency and separation rate. Some part of the above configuration can be flexibly selected according to your budget and requirements.

Working process of cable recycling separator machine

Working process of cable recycling separator machine

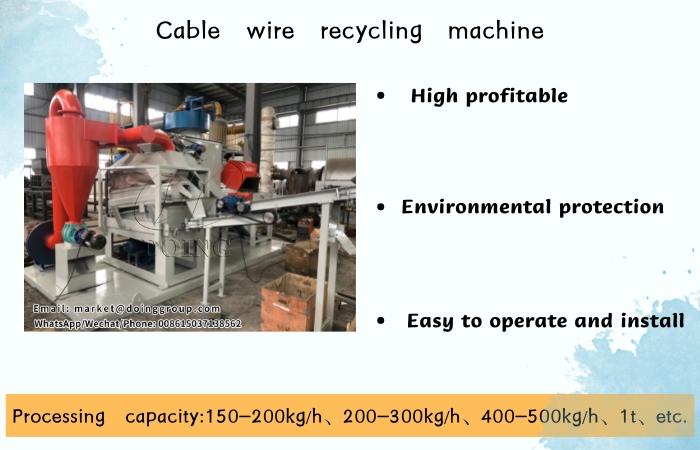

Cable recycling separator machine's features

1.With the electrostatic separator, the machine achieves an almost 100% metal recovery rate.

2.The rotor of the grinder is alternating,leading to more efficiency,faster discharging,lower noise and more steady running.

3.Using PLC control, uniform feed, intelligent operation, maximum guarantee machine's stable work.

4. Adapting dry and physical separating, don't damage the quality of metals and no secondary pollution, totally environmental friendly.

5.The crusher adopts double roller,low speed, high tear produces big output while little noise.

6.Suitable structure and layout, easy to install.

7.The design of separator and dust collector is handy for movement or transport.

Features of cable recycling separator machine

Features of cable recycling separator machine

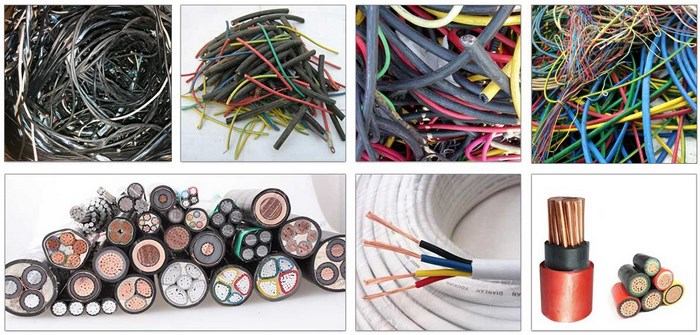

Cable recycling separator machine's raw material

For our cable recycling separator machine , please check the available raw materials as below:

All kinds of scrap wires, cable wire, aluminium wire, such as automobile electric line, motorcycle electric line, storage battery electric line, waste household appliance disassembly electric line, electro-mechanical equipment disassembly electric line, computer cable, telephone wire, cable TV line, communication cable and other scrap wires which are difficult to recycle, circuit board, copper-clad plate, etc.

If you worry about effect, we provide testing service for your raw materials. Besides, our engineers and salesmen will provide the suitable scheme for you in order to maximized your profits.

Raw materials

Raw materials

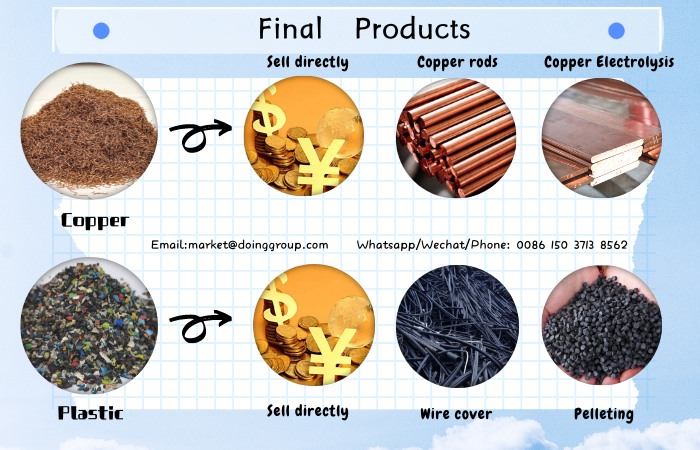

Cable recycling separator machine's final products

The separated copper obtained from the cable recycling separator machine can be easily sold to copper granulator collectors or individuals engaged in metal recovery for monetary gain. In the case of large quantities of copper, it is possible to directly sell it to copper electrolytic plants or copper factories.

As for the plastic, it can be sold to plastic collectors. The plastic can be processed into pellets and used to manufacture various new plastic products such as rubber mattresses, insoles, and even wire covers.

Final products

Final products

This increased demand has led to a substantial rise in copper prices. From a long-term perspective, cable recycling separator machine not only offers profitable opportunities but also contributes to environmental protection. It is indeed a business with great potential.

If you have any interest in the machine and would like to gather more information, please don't hesitate to contact us. We are committed to offering you our utmost support.

Leave Message

Please kindly leave your requirements in detail, or contact us via +86 15037138562. Our professional sales manager will contact you within 24 hours. Your contact information will be protected.

- QWhat machine do you want to learn about?

- Solar Panel Recycling Machine

- Lithium Battery Recycling Machine

- E-waste PCB Recycling Machine

- Copper Wire Recycling Machine

- Carbonization Pyrolysis Machine

- Radiator Recycling Machine

- Aluminum Plastic Recycling Machine

- Other:

- QWhat raw material do you want to process?

- Bamboo

- Wood

- Sawdust

- Coconut shell

- Palm Kernel Shell

- Wood Chips

- Not decided yet

- Other:

- QMachine processing capacity (tons of feedstock)

- Other:

- Not decided yet

- QWhat final product do you mainly want to obtain? For what applications?