1.Copper cable separation recycling machine introduction:

Copper cable separation recycling machine

Copper cable separation recycling machine

Copper cable separation recycling machine is dry type structure, adopting air and vibration separation technology, no water pollution. Copper cable separation recycling machine is mainly used to process all kinds of waste copper cables and wires into tiny copper particles and PVC particles, so it is also called cable granulator.

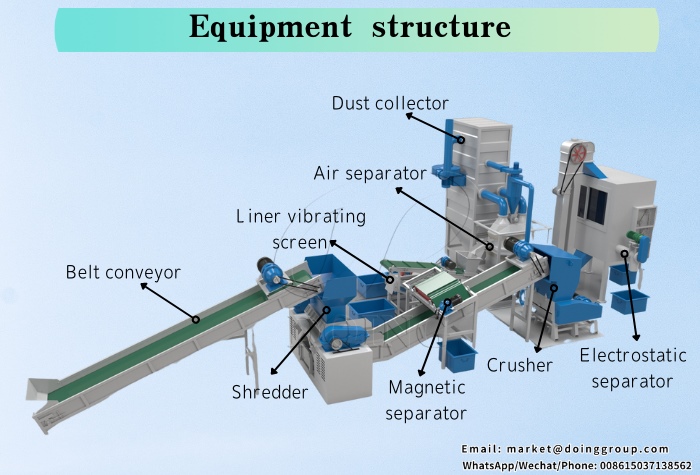

2. The equipment structure of copper cable separation recycling machine:

Equipment structure

Equipment structure

As the 3D picture shows, DY-600/800/1000/1200 medium/large scale copper cable separation recycling machine is made up of a dual shaft shredder, two conveying machines, a crusher, magnetic separator, air separator, vibrating screen and electrostatic separator, dust collecting system, etc.

DY-400 copper cable separation recycling machine

DY-400 copper cable separation recycling machine

DY-400 small scale copper cable separation recycling machine contains a crusher, air separator and dust collecting system.

3. The working process of copper cable separation recycling machine:

At first, the shredder will cut the materials into 10-15 mm pieces.

Then the crusher will crush the materials into 3-5 mm before further separation.

Third, the magnetic separator will remove the iron out.

Fourth, air separator will separate the copper and plastic. And they will flow out at different outlets.

Fifth, the vibrating screen can make the separating process much easier, and improve the purity of copper. Because the copper granules and copper sheets that can not through the screen of vibrating screen will be filtered out.

Besides, dust collecting system can collect dust to make the workshop clean and no pollution.

4.The advantages of DOING copper cable separation recycling machine:

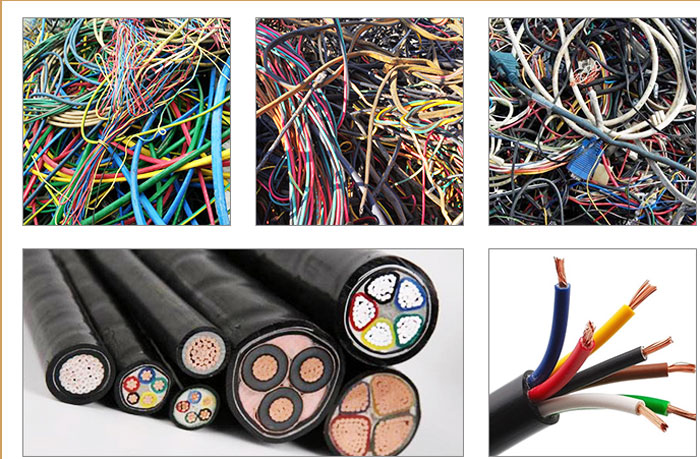

1.Wide Application: DOING copper cable separation recycling machine is designed to recycle various kinds of wires and cables with diameter between 1-20mm.

Various waste cable wires

Various waste cable wires

2. High separation rate: the separation rate of DY-400 copper cable separation recycling machine can reach 97%. And that of large scale copper cable separation recycling machine can reach up to 99%.

3. Environment-friendly: copper cable separation recycling machine has solved the pollution caused by the burning of the copper wires. With high copper recycling rate of 95%--99.99%, the device is with excellent dust removal performance because of the adoption of the fully closed production model.

5. The profit analysis of copper cable separation recycling business:

| Running cost / Day | |||||

| Item | Input | Quantity | Price | Input cost | Total cost |

| 1 | Scrap car wires | 500kg/h * 8h = 4T | USD3355 / ton | USD13420 | USD13522 |

| 2 | Power consumption | 65Kw/H * 8H = 520KwH | USD0.1/ KWH | USD52 | |

| 3 | Workers | 2 workers | USD25per one | USD50 | |

| Income / Day | |||||

| Item | Output | Quantity | Price | Income | Total income |

| 1 | Copper | 4T *55%= 2.2T | USD9422/ ton | USD20728.4 | USD 20953.4 |

| 2 | Plastic | 1.8T | USD125/ ton | USD225 | |

| Daily Profit = USD 20953.4– USD 13522 = USD 7431.4 | |||||

Copper cable separation recycling business can not only help you recycle waste cables and wires to make money, but also solve the problem of e-waste pollution and metal energy shortage.

6. The quality assurance of DOING copper cable separation recycling machine:

Before delivery, our all equipment will finish the real production test, use the customer need to deal with material, to ensure the production line performance and production can meet customer requirement. If you have requirement, we sincerely invite you came to the scene for final test or online to watch the testing process.

Leave Message

Please kindly leave your requirements in detail, or contact us via +86 15037138562. Our professional sales manager will contact you within 24 hours. Your contact information will be protected.

- QWhat machine do you want to learn about?

- Solar Panel Recycling Machine

- Lithium Battery Recycling Machine

- E-waste PCB Recycling Machine

- Copper Wire Recycling Machine

- Carbonization Pyrolysis Machine

- Radiator Recycling Machine

- Aluminum Plastic Recycling Machine

- Other:

- QWhat raw material do you want to process?

- Bamboo

- Wood

- Sawdust

- Coconut shell

- Palm Kernel Shell

- Wood Chips

- Not decided yet

- Other:

- QMachine processing capacity (tons of feedstock)

- Other:

- Not decided yet

- QWhat final product do you mainly want to obtain? For what applications?