Integrated copper wire recycling machine is an advanced technology that enables recycle copper from various sources, such as scrap telephone wires, car wiring, industrial cables, construction wires, cable manufacturing scraps, etc. with high efficiency and environmental protection. This integrated type copper wire recycling machine apply to different kinds of cable wires with a diameter of 3-40mm, the normal capacity is 200-300k/h, which can up to 600kg/h. The separation rate is higher as 99%.

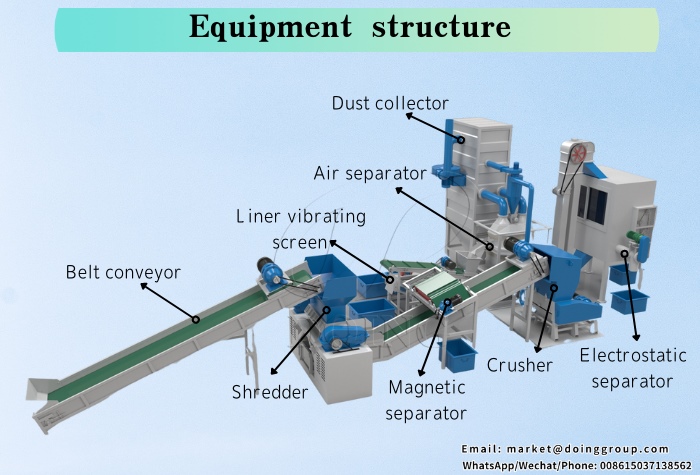

Configuration of integrated copper wire recycling machine:

Configuration of copper wire recycling machine

Configuration of copper wire recycling machine

Integrated copper wire recycling machine usually consists of a crusher, a magnetic separator and an air separator. With this configuration, integrated copper wire recycling machine can separate copper from plastic with the 99% separating rate. But if there are iron plug in waste cable wires, or very thin wires with the diameter below 3mm, an electrostatic separator is necessary. The whole configuration of integrated copper wire recycling machine includes shredder, magnetic separator, crusher, air separator and electrostatic separator.

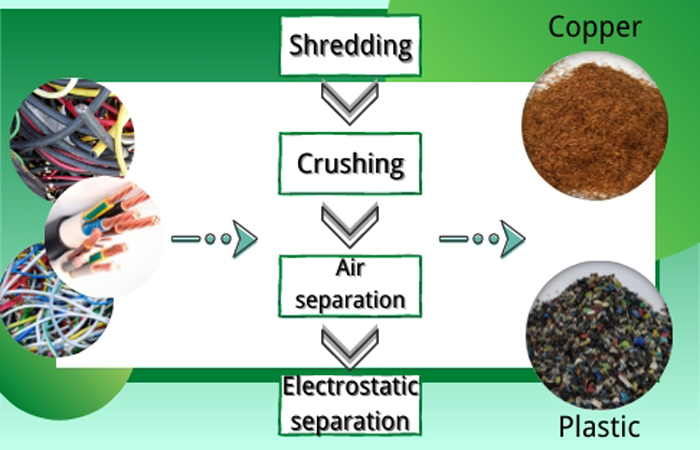

Working process of integrated copper wire recycling machine:

The working process of a integrated copper wire recycling machine involves several steps, which are as follows:

Step 1: Shredding

The first step of integrated copper wire recycling machine is shredding. The copper wires and cables are fed into the shredder, which will shred them into small pieces.

Step 2: Crushing

Then these small pieces will be fed into crusher, which further breaks them down into smaller particles.

Working process of copper wire recycling machine

Working process of copper wire recycling machine

Step 3: Air Separation

After the crushing process, these smaller particles will be sent into the air separator, then copper will be separated from plastic with the separating rate of 97%-98% according to their different gravity.

Step 4: Electrostatic Separation

The final step of integrated copper wire recycling machine is electrostatic separation. In this step, the copper granules will be separate from the remaining plastic granules in electrostatic separator, which takes advantage of the different conductivity of metal and non-metal in high-voltage electrostatic fields.

Final products of integrated copper wire recycling machine:

After processing, the final products we will get are copper and plastic.

Final products of copper wire recycling machine

Final products of copper wire recycling machine

Copper: The separated copper can be melted down and used to make new copper products, such as wires, pipes, and electrical components.

Plastic: The separated plastic can be recycled and used to make new plastic products, such as mouse, keyboard, shoes, and packaging materials.

[ Recommended Reading: Investment-profit analysis of copper wire granulator machine ]

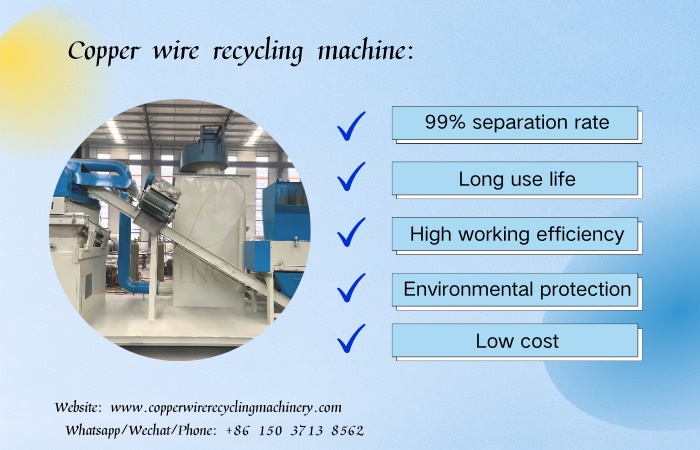

Features of integrated copper wire recycling machine:

1. Integrated structure, small dimensions, easy to move, saving space;

2. Low power consumption, energy saving;

3. Controlled by PLC control system, high degree of automatic;

Features of copper wire recycling machine

Features of copper wire recycling machine

4. No need in water, fire, or chemical solvent, environmental friendly;

5. Capacity and configuration can be customized as per your requirements.

We are experts in the field of solid waste recycling, especially metal recycling. We can provide a complete set of solutions, including waste cable wire recycling, waste circuit board recycling, waste radiators recycling, etc. If you have any need of our integrated copper wire recycling machine, feel free to contact Henan Doing Company.

Leave Message

Please kindly leave your requirements in detail, or contact us via +86 15037138562. Our professional sales manager will contact you within 24 hours. Your contact information will be protected.

- QWhat machine do you want to learn about?

- Solar Panel Recycling Machine

- Lithium Battery Recycling Machine

- E-waste PCB Recycling Machine

- Copper Wire Recycling Machine

- Carbonization Pyrolysis Machine

- Radiator Recycling Machine

- Aluminum Plastic Recycling Machine

- Other:

- QWhat raw material do you want to process?

- Bamboo

- Wood

- Sawdust

- Coconut shell

- Palm Kernel Shell

- Wood Chips

- Not decided yet

- Other:

- QMachine processing capacity (tons of feedstock)

- Other:

- Not decided yet

- QWhat final product do you mainly want to obtain? For what applications?