There are different kinds of copper cable separation machine, varies from small cable stripping machine to different capacties cable granulator. You can choose suitable copper cable separation machine based on your requirement.

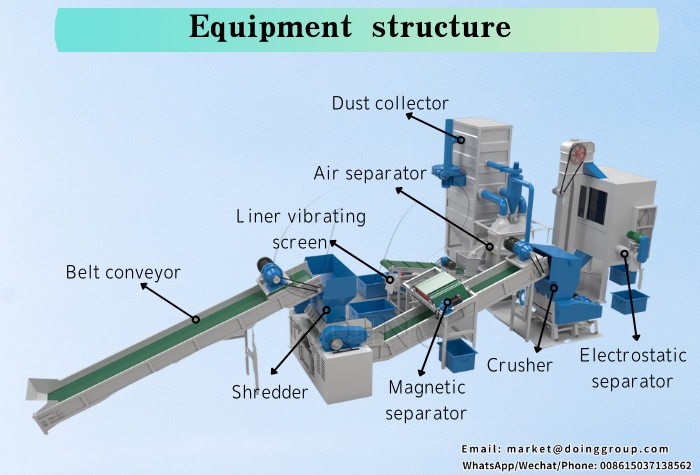

Equipment Structure

Equipment Structure

DOING mainly produces different capacties cable granulator, which is a kind of automatic copper cable separation machine, suitable for separating almost all kinds of cables and wires. And it is with high separation rate, no pollution.

The parameter of DOING copper cable separation machine:

| Capacity (kg/h) | Overall Dimension | Power(Kw) | Weight(Kg) | Recovery Rate |

| 100-150kg/h (DY-400) | 4000*2000*2300mm | 25kw | 1500kg | ≥99.9% |

| 200-300kg/h (DY-600) | 5000*4000*2500mm | 38kw | 3500kg | |

| 300-400kg/h (DY-800) | 6000*5000*4200mm | 65kw | 4500kg | |

| 500-600kg/h | 14000*6000*4200mm | 100kw | 7000kg | |

| 1000kg/h | 18000*14000*4200mm | 210kw | 10000kg | |

| 2000kg/h | 28000*20000*5000mm | 300kw | 15000kg |

As the above table shows, DOING copper cable separation machines' processing capacity is from 100kg/h to 2000kg/h, and we also can customize larger capacity for you, because we have our own engineer team and factory.

The working process of DOING copper cable separation machine:

The main working process of DOING copper cable separation machine is crushing and separating. We can see the detailed working process from above 3D video.

1. Crushing

There is shredder and crusher to process copper wires into small size particles. Shredder will pre-process the copper wires as 5-10cm. And the crusher will crush the wires as 3-4mm.

2. Separating

We will use magnetic separator, double layer magnetic separator, air separator and electrostatic separator to do the work in separating part.

The iron can be separated by magnetic separator and double layer magnetic separator. And the air separator and electrostatic separator will make the copper and plastic separated. The air separator will do the first separating process. If the copper are thick, the separation rate will get more than 99%. If the copper are thin, the separation rate will get about 97~98%. There will be 1-2% copper mixed in plastic, so it needs to use electrostatic separator to do the next separating process, and the separating rate can be above 99.9%. After separating by electrostatic separator, we will see there is no copper in plastic and no plastic in copper.

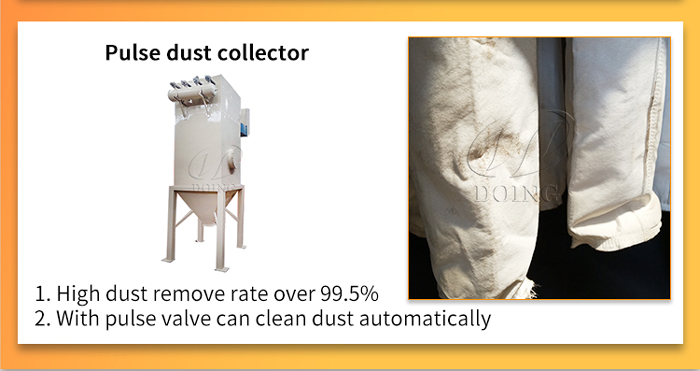

The dust removal system of DOING copper cable separation:

Copper cable separation machine

Copper cable separation machine

At the whole working process, there is pulse dust collector and cyclone dust collector to collect dust and keep the workshop clean. Besides, there is no other pollutions, very environmental friendly.

If you have aluminum wires or other kinds of waste cables or wires, you can tell us, and then our sales and engineer will give you detailed solution. Because it nees different configuration to process different kinds of cables and wires. Welcome to contact DOING!

Leave Message

Please kindly leave your requirements in detail, or contact us via +86 15037138562. Our professional sales manager will contact you within 24 hours. Your contact information will be protected.

- QWhat machine do you want to learn about?

- Solar Panel Recycling Machine

- Lithium Battery Recycling Machine

- E-waste PCB Recycling Machine

- Copper Wire Recycling Machine

- Carbonization Pyrolysis Machine

- Radiator Recycling Machine

- Aluminum Plastic Recycling Machine

- Other:

- QWhat raw material do you want to process?

- Bamboo

- Wood

- Sawdust

- Coconut shell

- Palm Kernel Shell

- Wood Chips

- Not decided yet

- Other:

- QMachine processing capacity (tons of feedstock)

- Other:

- Not decided yet

- QWhat final product do you mainly want to obtain? For what applications?