Industrial wire stripping machine

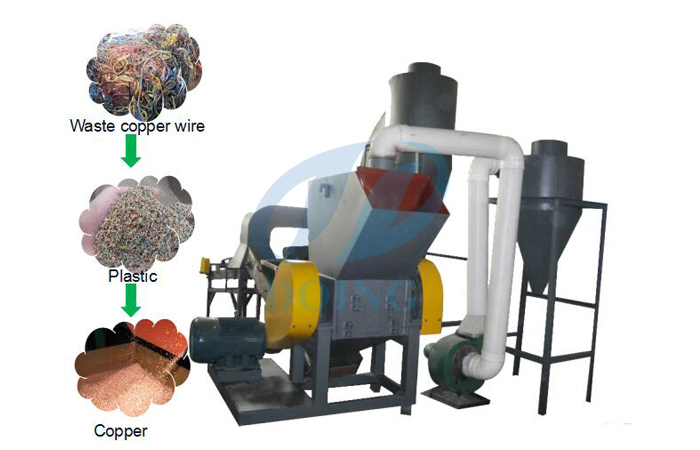

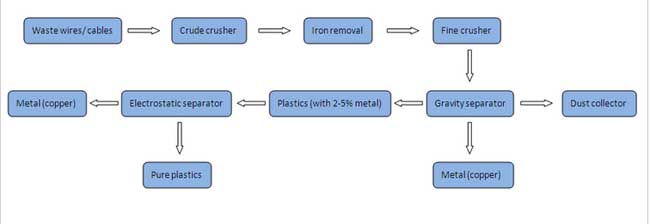

Industrial wire stripping machine process

Industrial wire stripping machine process

Industrial wire stripping machine feature:

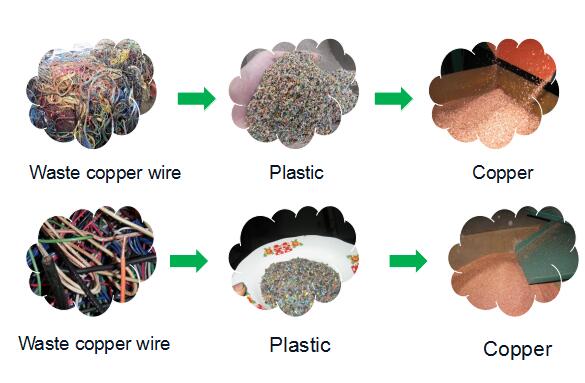

Industrial wire stripping machine final product

2.During the process of sorting, PE, PVC and copper are recycled with 99%.

And the separating copper has a purity up to 99%.

3.No pollution and Energy saving.

4.Waste Industrial wire stripping machine has a high degree of automation and is suited for customers who want efficient cable wire recycling with a minimum of manpower.

Leave Message

Please kindly leave your requirements in detail, or contact us via +86 15037138562. Our professional sales manager will contact you within 24 hours. Your contact information will be protected.

- QWhat machine do you want to learn about?

- Solar Panel Recycling Machine

- Lithium Battery Recycling Machine

- E-waste PCB Recycling Machine

- Copper Wire Recycling Machine

- Carbonization Pyrolysis Machine

- Radiator Recycling Machine

- Aluminum Plastic Recycling Machine

- Other:

- QWhat raw material do you want to process?

- Bamboo

- Wood

- Sawdust

- Coconut shell

- Palm Kernel Shell

- Wood Chips

- Not decided yet

- Other:

- QMachine processing capacity (tons of feedstock)

- Other:

- Not decided yet

- QWhat final product do you mainly want to obtain? For what applications?