PVC cable wire recycling machine is mainly used to separate copper and pvc plastic in waste wires and cables, because the separated metal is like rice grains, so it becomes a copper wire cable granulator.

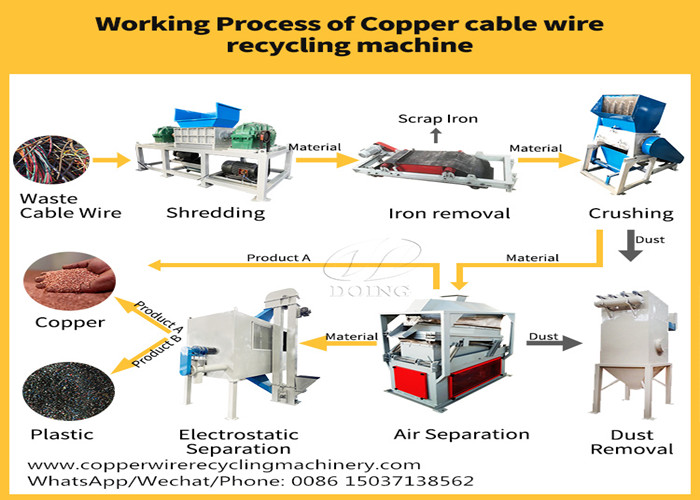

The configuration of DOING PVC cable wire recycling machine is mainly a shredder, crusher, self-unloading type magnetic separator, air separator, electrostatic separator, and pulse dust collector. Due to the characteristics of raw materials, the configuration of some part is different. Let us have a deeper understanding of each part according to the processing line.

Working process of PVC cable wire recycling machine

Working process of PVC cable wire recycling machine

The main function of the shredder is to pretreat the wire. For some thicker wires, the wires are entangled or the plug and the wire are mixed together, if you cut it directly, it may entangle the blade or damage the blade. It is recommended that you use a shredder to handle it.

There is a conveyor belt between the shredder and the crusher. If there is iron in the material, a magnetic separator is added to select the iron. The magnetic separator our company use is a self-unloading type magnetic separator, which automatically selects the material without manual cleaning. There is a device in the market, which is a simply magnet, and the efficiency of it will decrease when it is full of adsorption without manually remove.

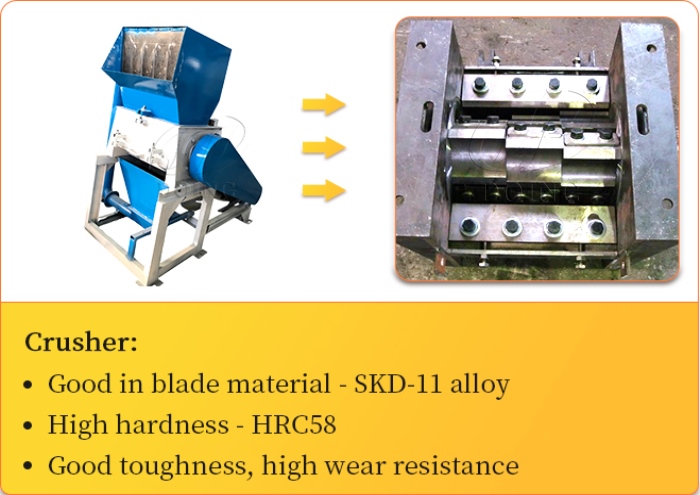

Crusher

Crusher

The material enters the crusher to be broken into particles, and the copper and pvc plastic are separated. The blade of our crusher is SKD-11. SKD-11 is a wear-resistant alloy steel, high carbon and high chromium has better wear resistance. There is a screen at the bottom of the crusher to control the size of the discharge. The discharge is determined according to the diameter of the wire, and the size of the screen is also based on the diameter of the wire.

The crushed material of the crusher is a mixture of copper and pvc plastic, and the next step is to sort. There are two modes of transportation from the crusher to the air separator, one is to use wind transportation, the other is belt conveyor. Wind transportation is fully enclosed transportation, and the overall appearance is also very clean, which reduces the leakage of materials and ash, and can also reduce the occupied area.

According to the principle of air suspension, the air separator suspends and separates copper and plastics with the same particle size due to the different forces received by different weights. The screen of the air separator is 180 mesh.

Air separator

Air separator

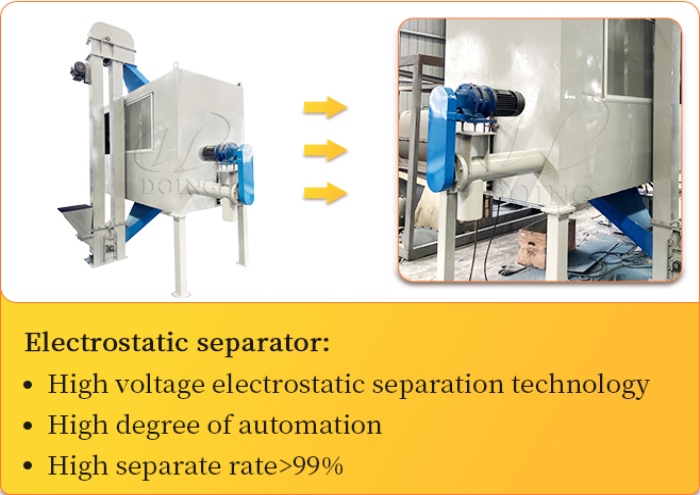

After sorting by the air separator, if your wire is a relatively thick copper wire, such as a square wire, the separation rate is almost 99%. If your line is more thin, there will be 2-3 points of copper loss. If you say that I don't want this copper to have too much loss, I want to put this 2-3 points The copper has been recycled. At this time, it is recommended that you add an electrostatic separator to the plastic outlet.

The electrostatic separator is mainly based on the different charging properties of metals and non-metals. When it goes out, the opposite-sex electricity of the non-metallic strip will be stuck on the roller and scraped off. After adding electrostatic separator, the recovery rate reaches more than 99.9%. The material sorted by the air separator is 1-4mm, and the material below 1mm can be separated by electrostatic separator . This is why electrostatics can improve sorting efficiency.

Electrostatic separator

Electrostatic separator

If your budget is limited, but you also want to recycle the copper lost in the plastic, you can also add a linear vibrating screen at the plastic outlet. Make the screen smaller to recover copper in pvc plastics. If there is a plug in your line, the flaky brass can be sieve out through a linear vibrating screen too.

The whole process only undergoes physical crushing and sorting, without using fire or chemicals. There is no secondary pollution, and the only existence is the ash generation. However, our company has a pulse dust removal system to collect ash, and the ash collection effect can reach more than 99.5%.

PVC cable wire recycling machine

PVC cable wire recycling machine

Besides, DOING PVC cable wire recycling machine has different processing capacity for you to choose, such as 100-150kg/h, 200-300kg/h, 300-400kg/h, 400-500kg/h, 500-600kg/h, 1-2t/h. You can choose the proper type of PVC cable wire recycling machine according your budget and business scale.

Henan Doing Company is specialized in waste recycling machine more than twelve years, we have own high qualified engineer team. If you interest in it, and want to know more details, please contact us.

Leave Message

Please kindly leave your requirements in detail, or contact us via +86 15037138562. Our professional sales manager will contact you within 24 hours. Your contact information will be protected.

- QWhat machine do you want to learn about?

- Solar Panel Recycling Machine

- Lithium Battery Recycling Machine

- E-waste PCB Recycling Machine

- Copper Wire Recycling Machine

- Carbonization Pyrolysis Machine

- Radiator Recycling Machine

- Aluminum Plastic Recycling Machine

- Other:

- QWhat raw material do you want to process?

- Bamboo

- Wood

- Sawdust

- Coconut shell

- Palm Kernel Shell

- Wood Chips

- Not decided yet

- Other:

- QMachine processing capacity (tons of feedstock)

- Other:

- Not decided yet

- QWhat final product do you mainly want to obtain? For what applications?