Product Details:

Scrap copper wire granulator

Scrap copper wire granulator

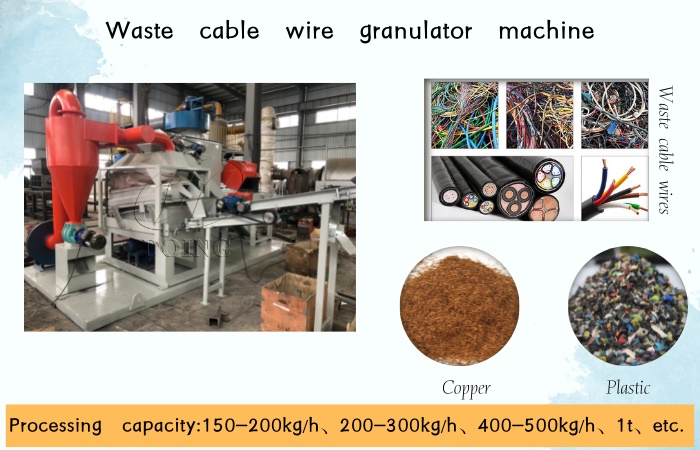

Scrap copper wire granulator is also known as waste cable wire recycling machine, which is mainly designed for separating pure copper from waste cables and wires. The capacity is about 200-1000kg/h. It adopts dry type physical separation method to process all kinds of waste cables and wires, which uses no water, chemical solution or fire, is an environmental friendly machinery. The separated copper is high quality, which can sell at a good price and earn more money.

Video Description:

This is a DY-600 scrap copper wire granulator working video send by our Argentina customer.

Customer place: Argentina

Raw materials: Various waste wires

Capacity: 200-300kg/h

Workers: 1-2 workers

Power: 50kw

Separating rate: 99%

Technical Data:

| Capacity (kg/h) | Overall Dimension | Power(Kw) | Weight(Kg) | Recovery Rate |

| 200-300kg/h | 5000*4000*2500mm | 38kw | 3500kg | ≥99% |

| 500-600kg/h | 14000*6000*4200mm | 100kw | 7000kg | |

| 1000kg/h | 18000*14000*4200mm | 210kw | 10000kg | |

| 2000kg/h | 28000*20000*5000mm | 300kw | 15000kg |

Main Structure:

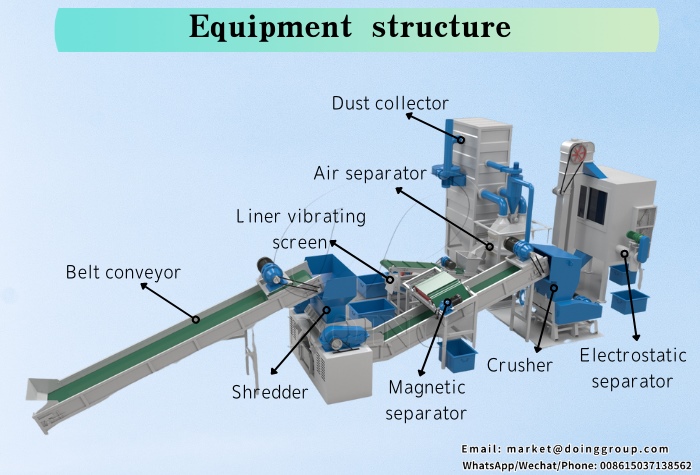

Equipment structure

Equipment structure

The main body of scrap copper wire granulator is consisted of crusher, air separator and dust collector. If the raw material contains waste wires with plugs, a shredder is required to pretreat the waste wires, and a magnetic separator is need to remove the iron. Besides, a linear vibrating screen is used to separate brass and copper. If you pursue a very high separating rate or the raw material contain very thin wires(Especially the diameter of copper wire is less than 3mm), an electrostatic separator is necessary to separate the fine copper from waste cables and wires.

Notable Features:

1. Adopted dry physical method to crush the waste cable wires into the mixture of metal and plastic, and separating copper from waste cable wires by air separator and electrostatic separator. The whole process won't produce any pollution to environment.

2. The scrap copper wire granulator is designed with an integrated type compact structure, which could save land occupy size and easy to install, debugging and transport.

Features of scrap copper wire granulator

Features of scrap copper wire granulator

3. Adopted advanced dry physical method recycling technology, which will not cause any pollution to water, soil, air, etc. Besides, the dust pollution problem is effectively solved by adding pulse dust and cyclone dust collector.

4. PLC control system makes the scrap copper wire granulator fully automatic with stable performance, and easy to operate, which save the labor cost.

5. The capacity of scrap copper wire granulator is 200-2000kg/h, if you have larger capacity needs, our engineer can customer suitable soultion for you.

Frequently Asked Questions:

Q: What is the product after separating?What can be used for?

A: The product after separating is mixed metals and resin fiber. Mixed metals can be extracted with chemical purification technology or sold in metal trading market. Resin powder can be processed into resin tiles, building brick fillers, floor paints, thermal insulation materials, fireproof materials, etc.

Q : Is your equipment environmentally friendly?

A: Electronic components dismantling machine has a flue gas purification system, which contains a spray tower for smoke removal and activated carbon adsorption and deodorization. PCB recycling machine has dust removal system, which includes cyclone dust collector and pulse dust collector.

Q: How is your PCB recycling machine installed?

A: We can arrange our engineer to guide the installation at the scene or online. Besides, we also attach installation labels to each accessory of the equipment, so that customer can independently complete the installation process.

Q: How should deal with the electronic components?

A: First pick out the chip before dismantling to avoid damage. Then capacitors can be selected by a magnetic separator. And tin can be collected out with a detinning furnace. You can sell them separately at high price. As for other electronic components, they can be sold together, but the price is a little low.

Scrap copper wire granulator

Scrap copper wire granulator

If you have other questions about scrap copper wire granulator, welcome to contact us. Our sales manager and engineer team will provide you professional suggestions.

Leave Message

Please kindly leave your requirements in detail, or contact us via +86 15037138562. Our professional sales manager will contact you within 24 hours. Your contact information will be protected.

- QWhat machine do you want to learn about?

- Solar Panel Recycling Machine

- Lithium Battery Recycling Machine

- E-waste PCB Recycling Machine

- Copper Wire Recycling Machine

- Carbonization Pyrolysis Machine

- Radiator Recycling Machine

- Aluminum Plastic Recycling Machine

- Other:

- QWhat raw material do you want to process?

- Bamboo

- Wood

- Sawdust

- Coconut shell

- Palm Kernel Shell

- Wood Chips

- Not decided yet

- Other:

- QMachine processing capacity (tons of feedstock)

- Other:

- Not decided yet

- QWhat final product do you mainly want to obtain? For what applications?