Henan Doing scrap copper wire recycling machine is designed for recycling waste cables and wires to separate copper from plastic out.

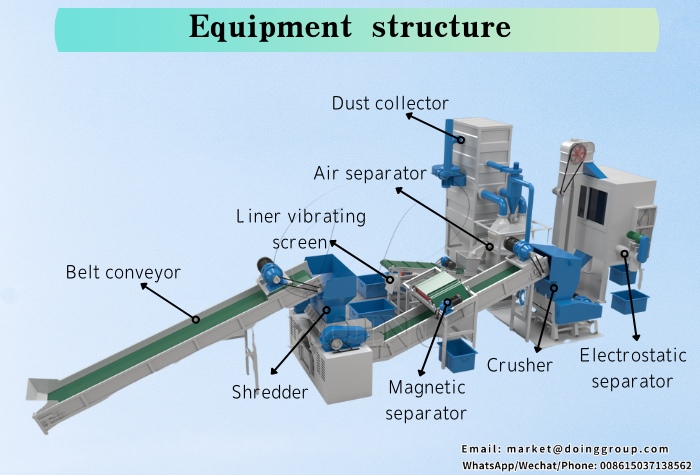

Equipment structure of scrap copper wire recycling machine:

Equipment structure

Equipment structure

Shredder: Shredder is used to pre-process waste cables and wires, to shred them into small pieces;

Crusher: Crusher can crush these small pieces into small particles;

Air separator: Air separator takes advantages of the different gravity of copper and plastic, to separate copper from plastic.

Electrostatic separator: Due to the crushing, the gravity of some copper may be similar with the plastic, air separator can't separate them clearly; electrostatic separator uses the different conductivity of metals and non-metals, it can separate the fine copper from the plastic particles.

Liner-vibrating screen: If the waste cables and wires have plug, liner-vibrating screen can be used to separate brass from copper.

Here is a 3D working video of our scrap copper wire recycling machine, which can help get a better understanding of the structure and the working process.

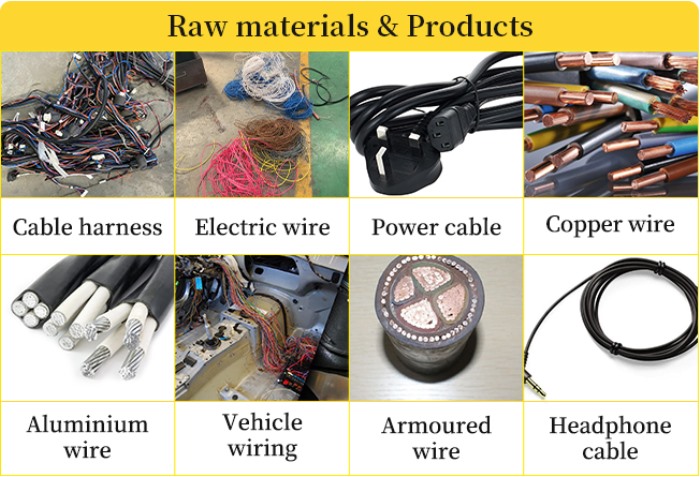

Application scope of scrap copper wire recycling machine:

Different types of waste cable wires

Different types of waste cable wires

Scrap copper wire recycling machine is used for all kinds of automotive wires, communication cables, and other cables and various miscellaneous cables, which can be collected from recycling centers, car dismantling plants, home appliance recycling and dismantling centers, scraps from cable wire manufacturers, etc.

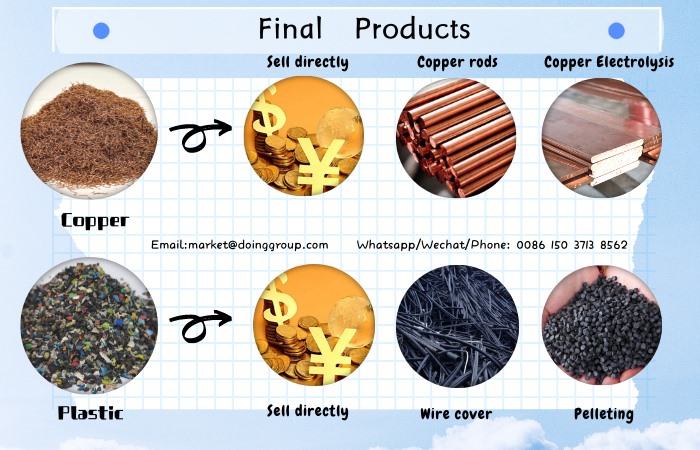

Final products of scrap copper wire recycling machine:

The waste cables and wires are made of copper(or aluminum) and plastic, so the final products of scrap copper wire recycling machine is copper(or aluminum) and plastic.

Copper: The separated copper is called red copper, which has high quality. It can be sold in the metal trading market directly, or you can make new products, like copper ingots, copper electrolysis, and then sell. At the current selling price, it can be sold around $7,700/ton.

Final products and application

Final products and application

Plastic: As for plastic, it can be sold directly as well. Or you can pellet the plastic into other products, like wire cover, tray, blister sheet, etc..

[ Recommended Reading: Investment-profit analysis of copper wire granulator machine ]

Tech parameter of scrap copper wire recycling machine:

| Capacity (kg/h) | Overall Dimension | Power(Kw) | Weight(Kg) | Recovery Rate |

| 200-300kg/h | 5000*4000*2500mm | 38kw | 3500kg | ≥99% |

| 500-600kg/h | 14000*6000*4200mm | 100kw | 7000kg | |

| 1000kg/h | 18000*14000*4200mm | 210kw | 10000kg | |

| 2000kg/h | 28000*20000*5000mm | 300kw | 15000kg |

Features of scrap copper wire recycling machine:

1. Scrap copper wire recycling machine adopts dust removal device, effectively solving the problem of dust pollution, ensure there is no dust fly and the working environment clean.

2. Scrap copper wire recycling machine adopts dry type physical separating method. The working principle is crushing and separating, so there is no secondary pollution to the environment.

3. Scrap copper wire recycling machine adopts a multi-machine combination structure to feed at one time, and complete it with multiple machines. Only one or two workers can operate the scrap copper wire recycling machine.

4. Scrap copper wire recycling machine can recycle both copper and plastic and can maintain the quality of the original copper, which can produce greater economic benefits.

Successful projects of scrap copper wire recycling machine:

Henan Doing Environmental Protection Technology Co., Ltd has rich experience of scrap copper wire recycling machinery manufacturing over 10 years, and has installed machine in India, Ethiopia, Ireland, Greece, Singapore, etc. Welcome to contact us, if you are interested in our scrap copper wire recycling machine.

Leave Message

Please kindly leave your requirements in detail, or contact us via +86 15037138562. Our professional sales manager will contact you within 24 hours. Your contact information will be protected.

- QWhat machine do you want to learn about?

- Solar Panel Recycling Machine

- Lithium Battery Recycling Machine

- E-waste PCB Recycling Machine

- Copper Wire Recycling Machine

- Carbonization Pyrolysis Machine

- Radiator Recycling Machine

- Aluminum Plastic Recycling Machine

- Other:

- QWhat raw material do you want to process?

- Bamboo

- Wood

- Sawdust

- Coconut shell

- Palm Kernel Shell

- Wood Chips

- Not decided yet

- Other:

- QMachine processing capacity (tons of feedstock)

- Other:

- Not decided yet

- QWhat final product do you mainly want to obtain? For what applications?