Scrap copper cable wire stripping tool

Raw material of Scrap copper cable wire stripping tool

Raw material of Scrap copper cable wire stripping tool

- All kinds of scrap wires, copper wire, aluminum wire, such as automobile electric line, motorcycle electric line, storage battery electric line, waste household appliance disassembly electric line, electromechanical equipment disassembly electric line, computer cable, telephone wire, cable TV line, communication cable and other scrap wires which are difficult to recycle, copper-clad plate, etc

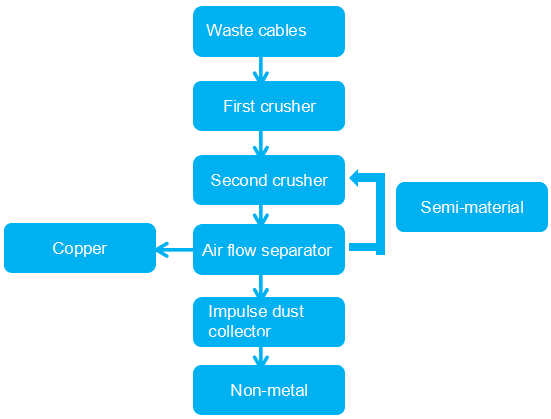

Scrap copper cable wire stripping tool working process

Scrap copper cable wire stripping toolworking process

Please make sure Scrap copper cable wire stripping tool and another equipments are in good condition. Then start the machine, and keep the machine running unloaded for 5-10 minutes before feeding.

Attention:

Boot sequence: suction fan1→suction fan 2→blower-feeding blower →riddler→mainframe.

Shutdown sequence: Riddler→blower→suction fan1→suction fan

2→feeding blower→mainframe

2. Feeding

Before feeding, pick up the debris especially the iron from the wires in case of the damage to the crusher blades. During the feeding period, the feeding speed should be in accordance with the crushing speed.

3. Fine crushing

If there is any abnormal noise, please stop and check the crusher, or change different size screen.

If there is too much copper or the produced particles are relatively small during the production process, replace the screen and adjust the distance between the fixed knife and the moving one.

If the Scrap copper cable wire stripping tool is easy to overheat, stop the device and inspect the gearing.

4.Vibrating separator

After crushed, the mixed material will be delivered to vibrating device. The copper from vibrating separator is complete copper without plastic, while the copper clad from the opposite discharging hole needs the second crushing.

Technical data of Scrap copper cable wire stripping tool

We will get copper and plastic by Scrap copper cable wire stripping tool

| Model | Voltage | Power | Capacity | Dimension | Weight |

| DYTM-400 | 380V | 22.45 kw | 150-200kg/H | 2700*1900*2300(mm) | 1200kg |

| DYTM-600 | 380V | 36 kw | 300-400kg/H | 3500*1900*2700(mm) | 3000kg |

| DYTM-800 | 380V | 75 kw | 500-600kg/H | 5500*4500*3300(mm) | 8000k |

Leave Message

Please kindly leave your requirements in detail, or contact us via +86 15037138562. Our professional sales manager will contact you within 24 hours. Your contact information will be protected.

- QWhat machine do you want to learn about?

- Solar Panel Recycling Machine

- Lithium Battery Recycling Machine

- E-waste PCB Recycling Machine

- Copper Wire Recycling Machine

- Carbonization Pyrolysis Machine

- Radiator Recycling Machine

- Aluminum Plastic Recycling Machine

- Other:

- QWhat raw material do you want to process?

- Bamboo

- Wood

- Sawdust

- Coconut shell

- Palm Kernel Shell

- Wood Chips

- Not decided yet

- Other:

- QMachine processing capacity (tons of feedstock)

- Other:

- Not decided yet

- QWhat final product do you mainly want to obtain? For what applications?