I. Definition:

As for an ordinary air-conditioner condensers, the copper content is about 55%, the aluminum content is about 40%, and the iron content is about 5%. Our AC condenser radiator recycling machine is designed to separate copper, aluminum and iron from waste AC condenser radiators for people to recycle copper and aluminum to earn profit.

II. Input materials:

Raw materials

Raw materials

AC condenser radiator recycling machine can recycle various waste radiators in the waste air conditioners, cars, refrigerators, etc.

III. Output product:

Final products

Final products

After processed by AC condenser radiator recycling machine, the final products you can get will be pure copper, pure aluminum and pure iron, which can be sold directly to earn profit after recycling.

IV. Profit analysis:

The recycled copper, aluminium and iron can be sent directly to the metal market to be sold for money. This is because DOING's radiator recycling plant can achieve a separation rate of 99.9%. The table below is an analysis of the profitability of radiator recycling business with DOING's 500kg/h AC condenser radiator recycling machine, but there are differences in the prices of copper and aluminium in different cities, so this table is for reference only.

| Running cost / Day | |||||

| Item | Input | Quatity | Unit Price ($) | input cost ($) | total cost($) |

| 1 | Waste radiators | 500kg/h*8h=4T | 3100 | 12400 | 12513.72 |

| 2 | Power consumption | 62Kw/H*8H=496KwH | 0.14 | 70.86 | |

| 3 | Workers | 2 workers | 21.42/day | 42.86 | |

| Income/day | |||||

| Item | Output | Quantity | Price($) | Income($) | Total income($) |

| 1 | Copper | 4T*53%=2.12T | 3500/T | 7420 | 15844 |

| 2 | Aluminum | 4T*45%=1.8T | 1050/T | 8424 | |

| Daily profit = daily income - daily cost=15844-12513.72=3330.28 ($) | |||||

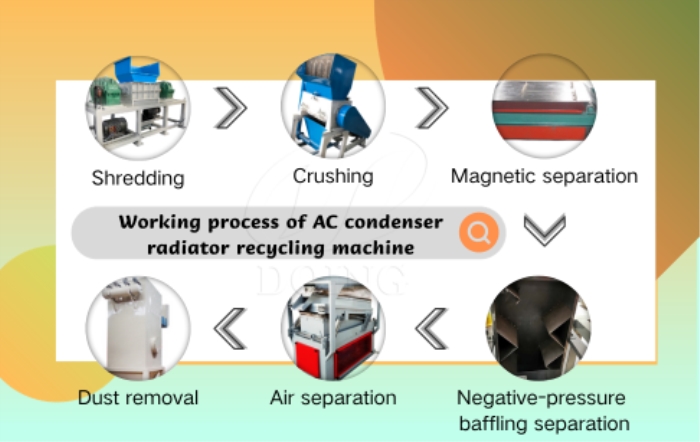

V. Working process:

1. Put the scrap radiator on the belt conveyor, which will sent them to the shredder or crusher;

2. After shredding and crushing, a mixed metal of about 2-3 mm of copper, aluminium and iron is obtained;

3. The magnetic separator will separate iron from copper and aluminum;

Working process

Working process

4. The negative-pressure baffling separator can separate 30% light aluminum from mixed metals.

5. Use the air separator to sort the copper and aluminum according to the principle of airflow suspension, using the different specific gravity of copper and aluminum;

6. In the working of the AC condenser radiator recycling machine, there are pulse dust and cyclone dust collectors to collect dust.

Here is a 3D working video of AC condenser radiator recycling machine, which can help you get a better understanding.

VI. Advantages:

High separation rate - Using a horizontal long-hole screen crusher, the phenomenon of copper-clad aluminum will not occur and the sorting effect is good.

High working efficiency - There are many different processing capacities to be chosen, varing from 500 to 2000 kg/h.

Low cost - With PLC control system, it only needs 1-2 workers to operate, and it is small footprint, which only needs a small land to install it.

Environmental friendly - It adopts dry type physical separation methods, which will not produce waste water, air, fire or toxic chemicals.

VII. Project case:

Henan Doing Environmental Protection Technology Co., Ltd has focused on the manufacture of recycling machines for more than ten years, and has successfully installed AC condenser radiator recycling machine in many countries, such as Australia, China, Thailand and so on.

Project case 1: Thailand 500kg/h radiator crushing and separation machine project was successfully installed and put into production

Project case 2: DOING copper aluminum radiator recycling machine was installed successfully in Hunan, China

AC condenser radiator recycling machine

AC condenser radiator recycling machine

AC condenser radiator recycling machine is a fast payback machine. More information about AC condenser radiator recycling machine, welcome to contact Henan Doing Environmental Protection Technology Co., Ltd.

Leave Message

Please kindly leave your requirements in detail, or contact us via +86 15037138562. Our professional sales manager will contact you within 24 hours. Your contact information will be protected.

- QWhat machine do you want to learn about?

- Solar Panel Recycling Machine

- Lithium Battery Recycling Machine

- E-waste PCB Recycling Machine

- Copper Wire Recycling Machine

- Carbonization Pyrolysis Machine

- Radiator Recycling Machine

- Aluminum Plastic Recycling Machine

- Other:

- QWhat raw material do you want to process?

- Bamboo

- Wood

- Sawdust

- Coconut shell

- Palm Kernel Shell

- Wood Chips

- Not decided yet

- Other:

- QMachine processing capacity (tons of feedstock)

- Other:

- Not decided yet

- QWhat final product do you mainly want to obtain? For what applications?