DOING has two kinds of AC radiator separator machine. One is stripping-type small AC radiator separator machine, and the other is crushing-type large AC radiator separator machine. Which one is suitable is based on the condition of your waste AC radiators. Next, DOING will introduce them for you.

1. Stripping-type small AC radiator separator machine

Stripping-type small AC radiator separator machine

Stripping-type small AC radiator separator machine

Stripping-type small AC radiator separator machine is suitable for processing flat waste AC radiators, and the daily processing capacity is not very large, under 600kg/h. Because of its low price, small footprint, it becomes the best choice for the investors who are going to start the radiators recycling business with small investment.

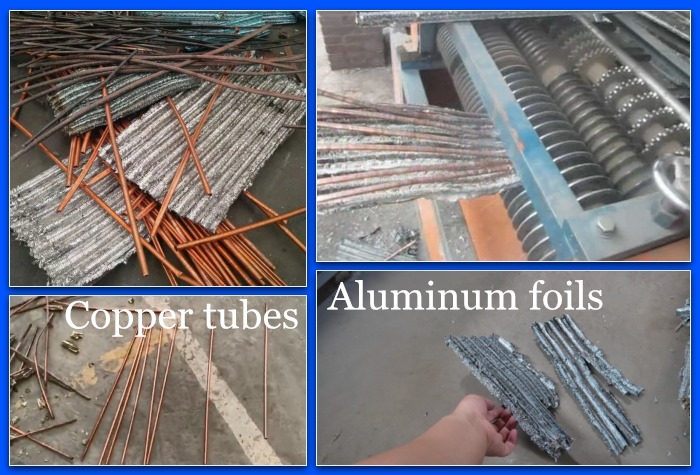

Stripping-type small AC radiator separator machine can separate both single and double layer AC radiators with the space size of copper tubes of 19mm, 21mm and 25mm. If your waste AC radiators are many layers, there is a radiator cutting machine as an auxiliary device.

After separating, you can get copper tube and aluminum foil, which can both be sold at a good price.

Final products of stripping-type small AC radiator separator machine

Final products of stripping-type small AC radiator separator machine

2. Crushing-type large AC radiator separator machine

Crushing-type large AC radiator separator machine can be used to process all kinds of waste AC radiators or car water tank, condensers, etc. Its daily processing capacity can reach up to 2000kg/h.

Crushing-type large AC radiator separator machine

Crushing-type large AC radiator separator machine

Crushing-type large AC radiator separator machine is full-automatically working, with PLC control system. And there is dust removal system, which make sure it is qualified the environmental requirements of each countries. So it is the best choice for waste recycling company.

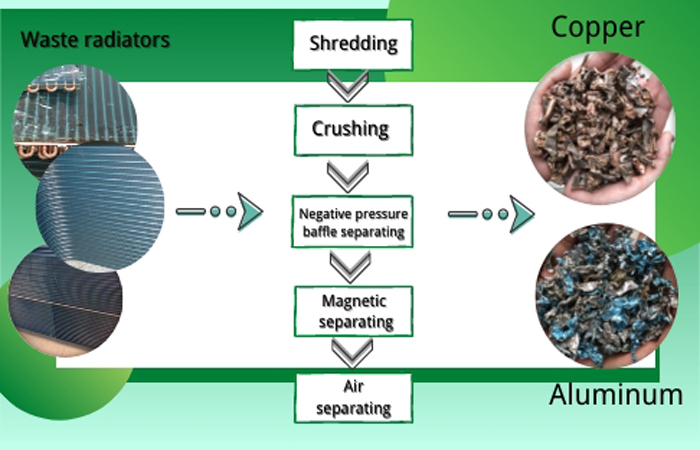

The working process of crushing-type large AC radiator separator machine: shredding -- crushing -- negative-pressure separating -- magnetic separating -- air separating.

Working process of crushing-type large AC radiator separator machine

Working process of crushing-type large AC radiator separator machine

1. Put radiators into shredder, to shred them into small pieces.

2. Use hammer crusher to crush small pieces into small particle in 2-3cm.

3. Use negative-pressure baffling separator to separate most aluminum first.

4. Use air separator to separate copper and rest aluminum.

5. During process, collect dust by pulse dust collector.

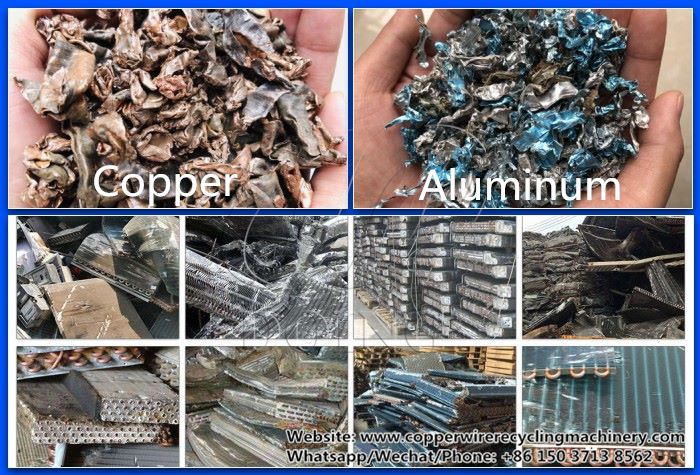

In the end, you can get pure lumps of copper, aluminum and iron. The separation rate can reach more than 99%.

Final products of crushing-type large AC radiator separator machine

Final products of crushing-type large AC radiator separator machine

So far, DOING AC radiator separator machine has exported to many countries, such as India, Australia, Palestine, Argentina, etc. If you want to buy AC radiator separator machine, you can contact us for free quotation and best service.

Leave Message

Please kindly leave your requirements in detail, or contact us via +86 15037138562. Our professional sales manager will contact you within 24 hours. Your contact information will be protected.

- QWhat machine do you want to learn about?

- Solar Panel Recycling Machine

- Lithium Battery Recycling Machine

- E-waste PCB Recycling Machine

- Copper Wire Recycling Machine

- Carbonization Pyrolysis Machine

- Radiator Recycling Machine

- Aluminum Plastic Recycling Machine

- Other:

- QWhat raw material do you want to process?

- Bamboo

- Wood

- Sawdust

- Coconut shell

- Palm Kernel Shell

- Wood Chips

- Not decided yet

- Other:

- QMachine processing capacity (tons of feedstock)

- Other:

- Not decided yet

- QWhat final product do you mainly want to obtain? For what applications?