Which advantages does waste aluminum plastic recycling equipment have?

Editor: Henan Doing

Date:December 14, 2023

Waste aluminum plastic recycling equipment is used to separate aluminum from plastic out of waste aluminum-plastic composite materials. With the advantages of high separation rate, environmental friendly, high working efficiency, wide application, low cost, high profit, etc., waste aluminum plastic recycling equipment has become the most popular recycling equipment in the aluminum plastic recycling industry. Next, let’s take a closer look at its advantages.

1. High separating rate

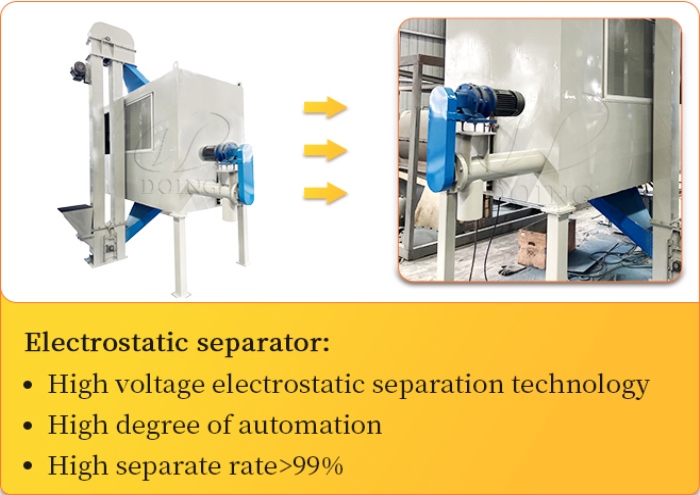

Electrostatic separator

Electrostatic separator

The separate rate of waste aluminum plastic recycling equipment is as high as 99%. The main reason is that it uses high pressure electrostatic separation technology to separate aluminum from plastic. Due to the different conductivity of aluminum and plastic, the separate rate is pretty high. In addition, in order to prevent the plastic from melting due to high temperature during the processing and adhering to the aluminum, thus affecting the overall separation rate, the waste aluminum and plastic recycling equipment is specially equipped with a circulating water cooling system to reduce the temperature and ensure a higher separation rate.

2. Environmental friendly

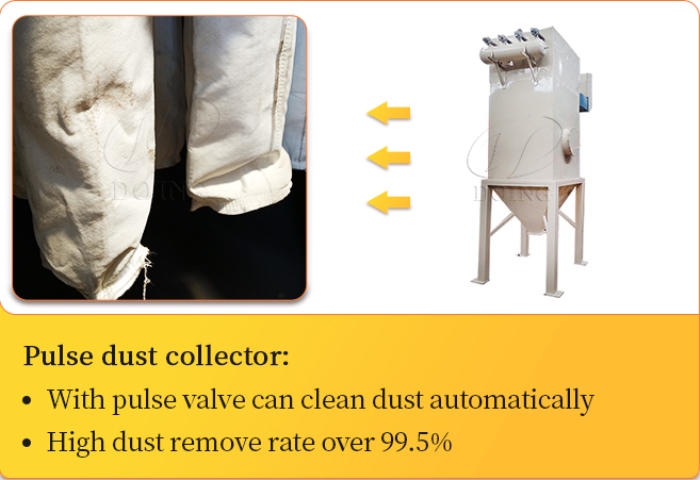

Pulse dust collector

Pulse dust collector

Waste aluminum plastic recycling equipment adopts dry type physical separation method, uses no water, no fire, or chemical solution. Moreover, it has pulse dust and cyclone dust collector to collect the dust with the collecting rate of 99.5%. The working sound is also lower than 85 decibels, which meets the industrial park standards. It is a totally environmental-friendly machine.

3. High working efficiency

Waste aluminum plastic recycling equipment is fully automatic in mechanical working way and its efficiency is increased 15% comparing with the manual way. The processing capacity is 200-1000kg/h, and if you want to process more waste aluminum-plastic composite materials, the capacity can be customized.

| Capacity (Kg/h) | Overall Dimension | Power (Kw) | Weight (Kg) | Recovery Rate |

| 200-300kg/h | 8500*4500*4200mm | 94kw | 6800kg | ≥99% |

| 300-400kg/h | 9500*5000*4200mm | 135kw | 7600kg | |

| 500-600kg/h | 11500*6500*4200mm | 316kw | 12600kg | |

| 800-1000kg/h | 16000*9000*4200mm | 483kw | 13500kg |

4. Wide application

Raw materials

Raw materials

Waste aluminum plastic recycling equipment can process many kinds of aluminum-plastic composite materials, like medical blister packs, aluminum composite panels, aluminum foils, toothpaste tube, aluminum plastic shaving, the leftover of aluminum-plastic composite materials, etc.

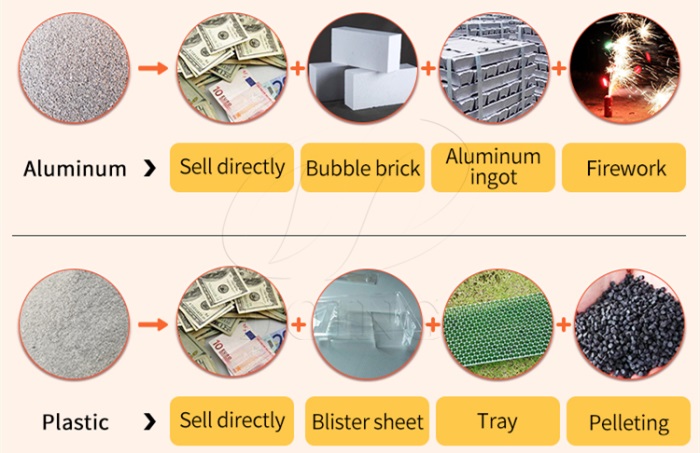

5. Low cost high profit

Final products' application

Final products' application

Waste aluminum plastic recycling equipment is controled by PLC control system, so it is easy to operate, only needs 1 or 2 workers to operate, which saves labor cost. In addition, low energy consumption and small footprint also save a lot of electricity costs and land costs. However, the purity of separated aluminum and plastic is high and the quality is good, which can be sold with a pretty higher price.

Henan Doing Company has been committed to the research, development and update of aluminum plastic recycling technology for years. The quality of the waste aluminum plastic recycling equipment for sale is stable and reliable, and the equipment has passed multiple qualification certifications. DOING brand enterprise is trustworthy!

Leave Message

Please kindly leave your requirements in detail, or contact us via +86 15037138562. Our professional sales manager will contact you within 24 hours. Your contact information will be protected.

- QWhat machine do you want to learn about?

- Solar Panel Recycling Machine

- Lithium Battery Recycling Machine

- E-waste PCB Recycling Machine

- Copper Wire Recycling Machine

- Carbonization Pyrolysis Machine

- Radiator Recycling Machine

- Aluminum Plastic Recycling Machine

- Other:

- QWhat raw material do you want to process?

- Bamboo

- Wood

- Sawdust

- Coconut shell

- Palm Kernel Shell

- Wood Chips

- Not decided yet

- Other:

- QMachine processing capacity (tons of feedstock)

- Other:

- Not decided yet

- QWhat final product do you mainly want to obtain? For what applications?