Product details:

Aluminum plastic sorting machine

Aluminum plastic sorting machine

Aluminum plastic sorting machine is used for processing waste aluminum composite materials, to get high purity and good quality aluminum and plastic, adopting dry type physical separation method.

Processing Raw Materials:

It can process waste aluminum plastic composite materials, like medical blister packs, aluminum composite panel(ACP) and aluminum foils.

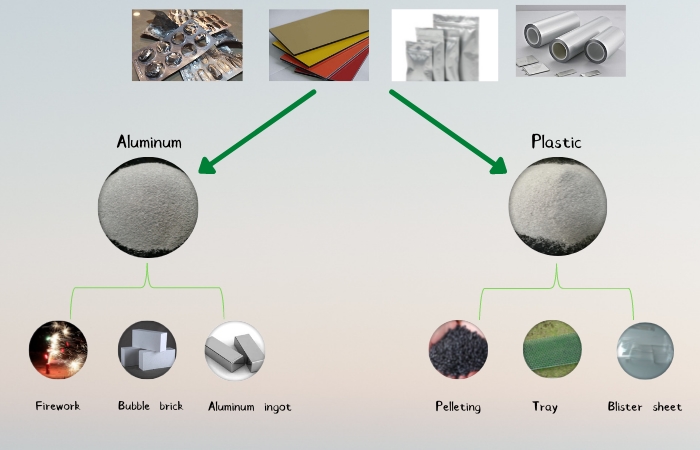

Raw materials and final products & application

Raw materials and final products & application

Final products and application:

Aluminum: It can be sold directly in the market, or it can be made to aluminum ingot, firework, bubble brick, etc.

Plastic: It can be made into blister sheet, tray, pelleting, etc.And it also can be sold directly.

Processing capacity:

| Capacity (Kg/h) | Overall Dimension | Power (Kw) | Weight (Kg) | Recovery Rate |

| 200-300kg/h | 8500*4500*4200mm | 94kw | 6800kg | ≥99% |

| 300-400kg/h | 9500*5000*4200mm | 135kw | 7600kg | |

| 500-600kg/h | 11500*6500*4200mm | 316kw | 12600kg | |

| 800-1000kg/h | 16000*9000*4200mm | 483kw | 13500kg |

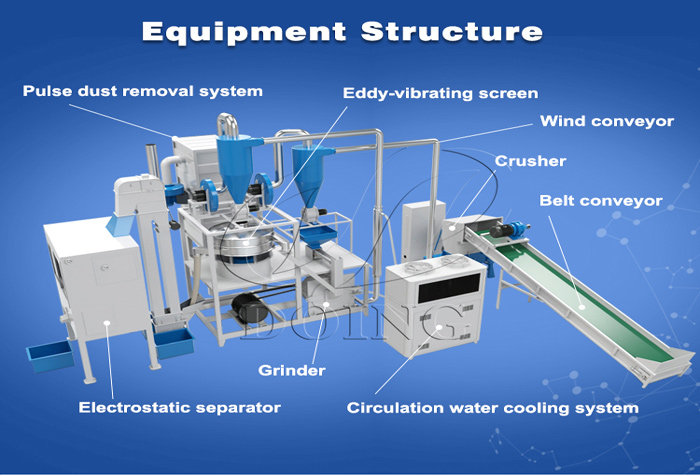

Configuration:

Configuration of aluminum plastic sorting machine

Configuration of aluminum plastic sorting machine

Different processing capacity has different configurations. The basic configuration of aluminum plastic sorting machine is consisted of belt conveyor, crusher, grinder, cooling system, eddy-vibrating screen, electrostatic separator and dust removal system.

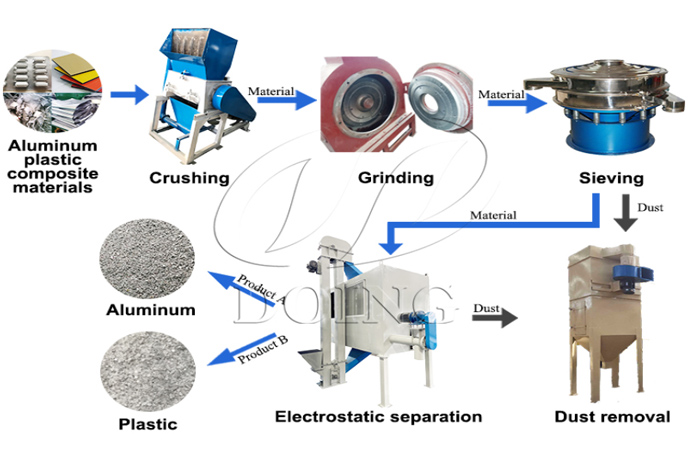

Working process:

Crushing - Grinding - cooling system - sieving - electrostatic separation

Aluminum plastic sorting machine working process

Aluminum plastic sorting machine working process

1. Input waste aluminum plastic composite materials into crusher, the waste aluminum plastic composite materials will be crushed into small particles.

2. Grinding the particles into powder by using a grinder.

3. Using an eddy-vibrating screen to control the size of powder.

4. Then use an electrostatic separator to separate aluminum and plastic.

5. During whole process, we collect the dust by using a pulse dust collector.

Features:

The crusher uses SKD-11 alloy blades with hardness in HRC58 which could ensure the good toughness under high wear resistance guarantee with the alternated splayed structure.

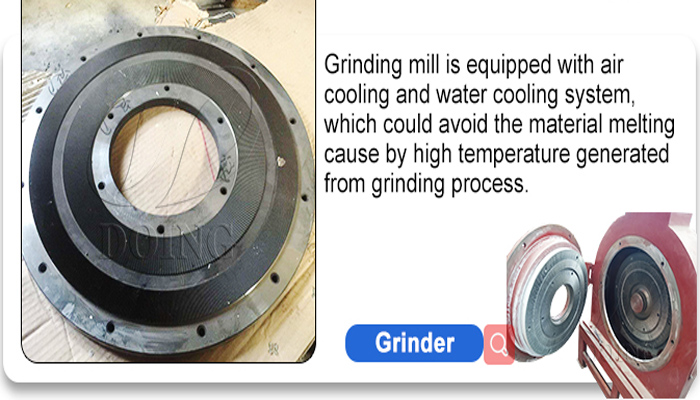

Grinding mill is equipped with air cooling and water cooling system, which could avoid the material melting cause by high temperature generated from grinding process.

Grinding mill

Grinding mill

Electrostatic separator can separate metal and plastic by high voltage electrostatic, along with bucket elevator to form an automatic sorting circle system to get high separate rate over 99.9%.

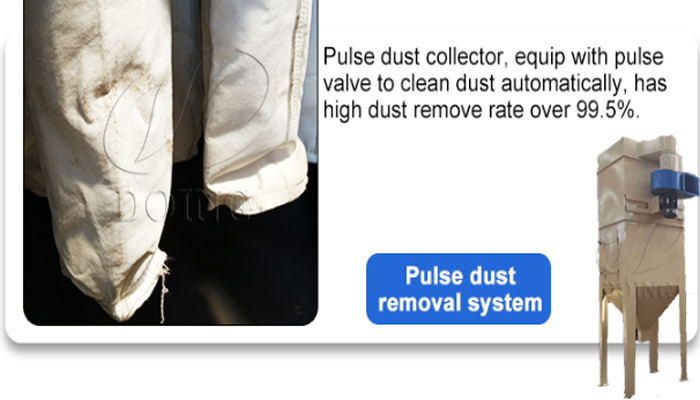

Pulse dust collector, equips with pulse valve to clean dust automatically, has high dust remove rate over 99.5%.

Pulse dust collector

Pulse dust collector

Henan Doing Environmental Protection Technology Co. Ltd. is a comprehensive environmental equipment manufacturer, integrating technological design, research and development, machine production, sales and after-sales service in one. The main products of Henan Doing are copper wire recycling machine, PCB recycling machine, aluminum plastic separation recycling machine, radiator recycling machine, etc. Our machines have been sold to 60 countries around the world.So if you are interested in this machine, welcome to contact us.

Leave Message

Please kindly leave your requirements in detail, or contact us via +86 15037138562. Our professional sales manager will contact you within 24 hours. Your contact information will be protected.

- QWhat machine do you want to learn about?

- Solar Panel Recycling Machine

- Lithium Battery Recycling Machine

- E-waste PCB Recycling Machine

- Copper Wire Recycling Machine

- Carbonization Pyrolysis Machine

- Radiator Recycling Machine

- Aluminum Plastic Recycling Machine

- Other:

- QWhat raw material do you want to process?

- Bamboo

- Wood

- Sawdust

- Coconut shell

- Palm Kernel Shell

- Wood Chips

- Not decided yet

- Other:

- QMachine processing capacity (tons of feedstock)

- Other:

- Not decided yet

- QWhat final product do you mainly want to obtain? For what applications?