In the past, people disposed e waste by fire and chemical reagent. But these two way will not only damage the quality of e waste, but also pollute the environment. So they are not the best methods to dispose e waste. With the development of e waste recycling technology, more and more people now use PCB board recycling machine to dispose of e waste, and this method is gradually recognized as the best way to dispose e waste. Then, you may have doubt why PCB board recycling machine is the best method of disposing e waste? Read on and you will find the answer.

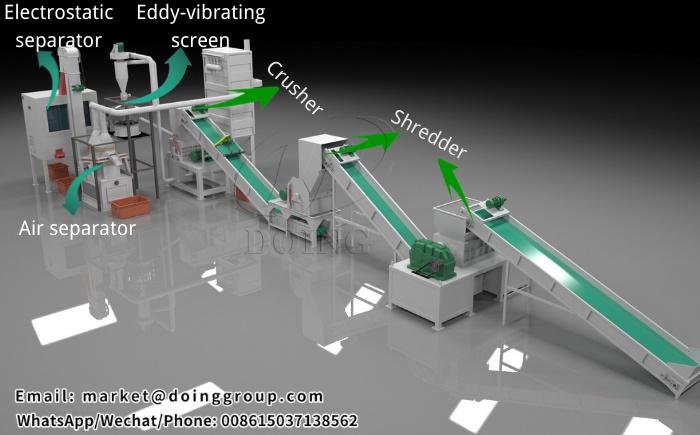

Process of PCB board recycling machine

The first reason is that PCB board recycling machine's processing is environmental friendly. Henan Doing Environmental Protection Technology Co., Ltd has various PCB board recycling machines, which adopt dry type separation method. The working process consists of shredding, crushing, sieving and separating. Compared to the fire and chemical reagent, the whole process will not use water, fire, chemical, which will not pollute the environment. Besides, it will not damage the quality of e waste, so you can recycle the e waste at the percent of 100. So it is a totally environmental friendly machine.

Components of PCB board recycling machine

Components of PCB board recycling machine

The second reason is that PCB board recycling machine's separation rate is pretty high. In general, one set PCB board recycling machine is made of shredder, crusher, eddy-vibrating screen, air separator and electrostatic separator. The electrostatic separator is used to separate metals and non-metals. Because metals and non-metals have different conductivities, electrostatic separator can separate them easily in a magnetic field. The separation rate even can reach to 99%.

| Capacity(Kg/h) | Overall Dimension | Power(Kw) | Weight(Kg) | Recovery Rate |

| 100-150kg/h | 8000*6000*4200mm | 42kw | 6000kg | ≥99% |

| 200-300kg/h | 10000*6000*4200mm | 76kw | 7500kg | |

| 400-500kg/h | 16000*8000*4200mm | 95kw | 8500kg | |

| 500-700kg/h | 21000*9000*4200mm | 140kw | 10000kg | |

| 800-1000kg/h | 24000*10000*4500mm | 250kw | 14000kg | |

| 1500-2000kg/h | 28000*20000*5000mm | 470kw | 19000kg |

The third reason is that PCB board recycling machine's working efficiency is also high. Compared to the traditional ways, PCB board recycling machine has larger processing capacities, varing from 100-150 kg/h to 1500-2000 kg/h, which can save a lot of time. And if you have larger processing capacity, we can custom-made. So you can process more e waste.

Advantages of PCB board recycling machine

Advantages of PCB board recycling machine

In addition, PCB board recycling machine can also save money cost on land, because it is small footprint, just needs a small land to install it. Besides, its operation is very easy, which just needs 1-2 workers to operate. So you just need to employee no more than 2 workers, which will save a great amount of money cost on labor force.

Above are the reasons of why PCB board recycling machine is the best method of disposing e waste. If you have doubt about the advantages PCB board recycling machine, welcome to test the PCB board recycling machine in our factory by yourself. Henan Doing Environmental Protection Technology Co., Ltd is welcomed to your visit.

Leave Message

Please kindly leave your requirements in detail, or contact us via +86 15037138562. Our professional sales manager will contact you within 24 hours. Your contact information will be protected.

- QWhat machine do you want to learn about?

- Solar Panel Recycling Machine

- Lithium Battery Recycling Machine

- E-waste PCB Recycling Machine

- Copper Wire Recycling Machine

- Carbonization Pyrolysis Machine

- Radiator Recycling Machine

- Aluminum Plastic Recycling Machine

- Other:

- QWhat raw material do you want to process?

- Bamboo

- Wood

- Sawdust

- Coconut shell

- Palm Kernel Shell

- Wood Chips

- Not decided yet

- Other:

- QMachine processing capacity (tons of feedstock)

- Other:

- Not decided yet

- QWhat final product do you mainly want to obtain? For what applications?