Circuit board recycling process machine

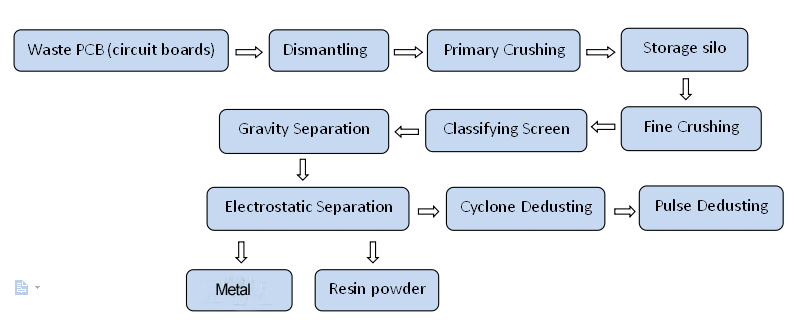

Circuit board recycling process machine working process

Circuit board recycling process machine

1. First crushing (let the big board to some small)

2. Secondary crushing (let the small board to powder)

3. Classifier

4. Separate the products.

Circuit board recycling process machine adopts physical recycling method, first of all, the waste circuit board become mixed powder (metal powder and resin fiber powder); And then through the air separation equipment and electrostatic separation equipment to separate metal powder and resin fiber powder. To prevent dust pollution in the process of production, Add pulse duster after the air separation process, can effectively solve the dust pollution problem.

Circuit board recycling process machine main feature

Circuit board recycling process machine final product

2. Processing ability strong, can handle a ton of circuit boards per hour, and low energy consumption, high separation rate;

3. The comprehensive performance is good, the computer board, computer boards, TV board and other circuit board can be recycled.

4. Low noise, high automation procedures, high efficiency, less land occupation;

5. No pollution, using pulse duster, well-knit structure, less land occupation, convenient installation;

Leave Message

Please kindly leave your requirements in detail, or contact us via +86 15037138562. Our professional sales manager will contact you within 24 hours. Your contact information will be protected.

- QWhat machine do you want to learn about?

- Solar Panel Recycling Machine

- Lithium Battery Recycling Machine

- E-waste PCB Recycling Machine

- Copper Wire Recycling Machine

- Carbonization Pyrolysis Machine

- Radiator Recycling Machine

- Aluminum Plastic Recycling Machine

- Other:

- QWhat raw material do you want to process?

- Bamboo

- Wood

- Sawdust

- Coconut shell

- Palm Kernel Shell

- Wood Chips

- Not decided yet

- Other:

- QMachine processing capacity (tons of feedstock)

- Other:

- Not decided yet

- QWhat final product do you mainly want to obtain? For what applications?