Printed electronic circuit board (PCB) is the foundation of electronic industry and an indispensable part in all kinds of electronic products. And the main components of electronics waste are Cu 20%, Fe 8%, Sn 4%, Ni 2%, Pb 2%, Al 2%, ZN 1%, SB 0.4%, Au 1000g/t, Pd 50g/t and other substance. All of these metals are very precious and valuable. As for the resin and fiber is also the good industry products.

Various waste printed circuit boards

Various waste printed circuit boards

If you want to recycle the mixed metals and the resins, you should adopt scientific and reasonable method to ensure getting high recycle rate. At present, the most studied recycling methods can be generally divided into mechanical treatment, heating treatment, hydro-metallurgy, biological treatment and supercritical method. Among them, eating treatment and mechanical treatment are the most common method in the industry.

1. Heating treatment techniques

Heating treatment techniques include traditional incineration and pyrolysis.

(1).Incineration

Incineration method

Incineration method

The incineration method is to crush the waste printed circuit board and send it to the incinerator for incineration. The residue obtained is metal and fiber. After that, it is recovered by physical and chemical methods. The whole recycling process is very complicated. In addition, improper temperature control during incineration can produce highly toxic substances. Therefore, the environmental protection requirements for incinerators and their pollution prevention and control facilities are extremely strict. So, Doing do not recommend this method.

(2). Pyrolysis

Pyrolysis method

Pyrolysis method

Pyrolysis is the use of anoxic or anaerobic conditions to decompose organic matter into gas, oil and glue to separate metal. Pyrolysis technology not only avoids the complicated separation process of technology and polymer materials, but also can recover heat energy and chemical materials from the pyrolysis products, with little environmental pollution. However, the technical process is complex and has not been applied in industrialization.

2. Mechanical treatment

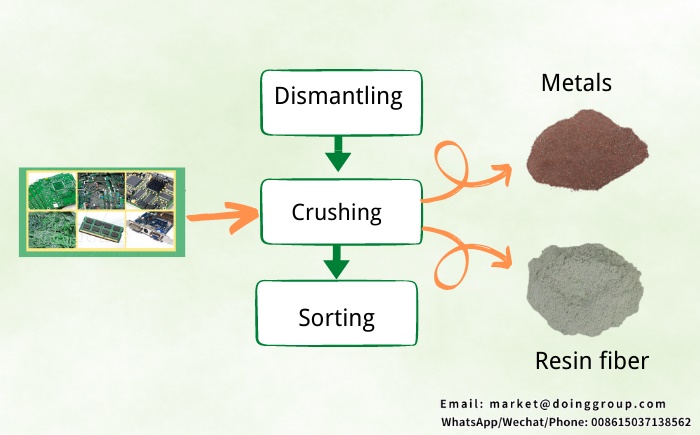

Mechanical treatment is an effective method for the pre-separation of different components of waste circuit board. The process is divided into three steps: dismantling, crushing and sorting.

Process of mechanical treatment

Process of mechanical treatment

(1)Dismantling is mainly to remove components and harmful substances on the printed circuit board.

(2)Crushing is to crush the PCB substrate into granular or powder, and the particle size varies according to different crushing methods.

(3)The main method of sorting is to take advantage of the differences in physical properties between substances, such as density, magnetism, electricity, surface properties and optical properties

Dry type PCB board recycling machine

Dry type PCB board recycling machine

In addition, there are two methods in mechanical treatment, including dry and physical type and wet type. But wet type produces waste water when processes PCB. While dry physical process is environmental method which is widely used in disposal PCB.

Doing introduces several method to recycle PCB above. If you have a great deal of PCB to recycle and have more questions, you can contact Doing. The engineers of Doing will provide solutions according to you needs.

Leave Message

Please kindly leave your requirements in detail, or contact us via +86 15037138562. Our professional sales manager will contact you within 24 hours. Your contact information will be protected.

- QWhat machine do you want to learn about?

- Solar Panel Recycling Machine

- Lithium Battery Recycling Machine

- E-waste PCB Recycling Machine

- Copper Wire Recycling Machine

- Carbonization Pyrolysis Machine

- Radiator Recycling Machine

- Aluminum Plastic Recycling Machine

- Other:

- QWhat raw material do you want to process?

- Bamboo

- Wood

- Sawdust

- Coconut shell

- Palm Kernel Shell

- Wood Chips

- Not decided yet

- Other:

- QMachine processing capacity (tons of feedstock)

- Other:

- Not decided yet

- QWhat final product do you mainly want to obtain? For what applications?