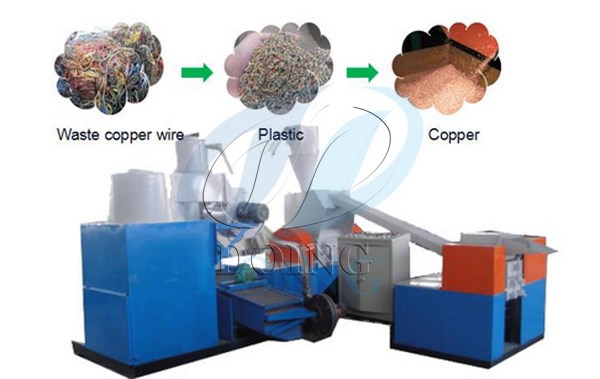

Copper wire recycling process is the process to separate copper and plastic for recycle use. According to the different input size of the copper wire, the corresponding copper wire recycling process are recommended as below:

Copper wire

Copper wire

1. For copper wire input size between 3-20mm,we advice the copper wire recycling process as crushing - air separation,

First, that because waste copper wire mainly consists of reinforced and copper wire attached, have the characteristic of higher hardness and toughness, but this features is easy to broken under the action of shear force and impact force. After we test, the average particle size of materials after knife crushing at 0.67-1mm, and we use the knife tool material is SKD-11 which is the high carbon and chromium alloy tool steel (one material of the more precision and longest lived of the world ).

After crushing, the second way to separate the copper and the plastic: We recommend using the airflow classification: the main principle of relative density: copper density(8.9g/cm3around) is higher much than Plastic(1.2g/cm3 around), when the material enters the air separator, the plastic particles with smaller density will be absorbed by the wind, And under the vibration of the air separator, it moves to the plastic end of the air separator. Because of the high density of copper particles, they cannot be absorbed by the wind. Under the action of vibration, these copper meters move to the copper outlet of the air separator.

2. For copper wire input size less than 3mm, we advice the copper wire recycling process as crushing – air separation – electrostatic separation.

Here more one process of static electricity separation, that because some very small diameter of copper, like 2mm, 1mm density is similar as plastic, this way will difficult to sorting, then we will use the static electricity.

Working principle: High frequency alternating magnetic field is produced on the surface of separating magnetic roll. When conductive nonferrous metal, like copper passes through magnetic field, eddy current will be induced in nonferrous metal. The eddy current itself produces a magnetic field opposite to the direction of the original magnetic field, while non-ferrous metals (such as copper, aluminum, etc.) will leap forward along their transport direction due to the repulsive force of the magnetic field, thus separating them from other non-metallic substances. The main distinguishing criterion is the ratio of material conductivity and density. Material with high ratio is easier to separate than that with low ratio.

3. For copper wire input size bigger than 20mm, we recommend the copper wire recycling process as shredding – crushing – air separation – electrostatic separation.

Why here add one copper wire recycling process of Shredding? That because the diameter of copper wire diameter is bigger, if we crushing them by the knife directly, the damage of the knife tool is very serious. So here we add the Shredding machine. And because here we deal with the metal and non-metal, so here we choose the two-axle shredder:

Working principle: The two rotors then clamp the material under the blade through the blade, and crush the material through the high torque rotor belt.

After we test that it can tear up the copper max thickness at 6mm, the diameter at 20-80mm and after shred, the debris diameter at 3-5mm, then we smash the copper wire again to use the Knife crushing.

Copper wire recycling machine

Copper wire recycling machine

Except the basic separation process as above, copper wire recycling machine manufactured by Henan Doing Company also equipped with dust removal system which could remove dust from the crushing and separation process, which ensure no dust pollution to the air. More details, please feel free to contact us. We’ll provide you the specific technical support.

Leave Message

Please kindly leave your requirements in detail, or contact us via +86 15037138562. Our professional sales manager will contact you within 24 hours. Your contact information will be protected.

- QWhat machine do you want to learn about?

- Solar Panel Recycling Machine

- Lithium Battery Recycling Machine

- E-waste PCB Recycling Machine

- Copper Wire Recycling Machine

- Carbonization Pyrolysis Machine

- Radiator Recycling Machine

- Aluminum Plastic Recycling Machine

- Other:

- QWhat raw material do you want to process?

- Bamboo

- Wood

- Sawdust

- Coconut shell

- Palm Kernel Shell

- Wood Chips

- Not decided yet

- Other:

- QMachine processing capacity (tons of feedstock)

- Other:

- Not decided yet

- QWhat final product do you mainly want to obtain? For what applications?