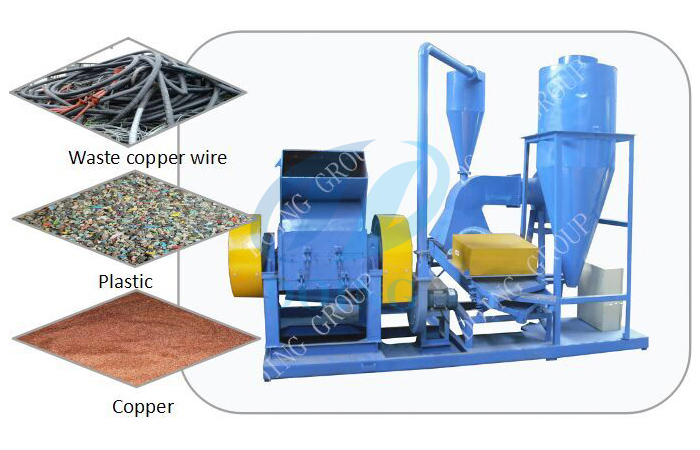

Used copper wire separator, also named copper wire recycling machine, is used for separating copper from plastic. Usde copper wire separator belongs to environmental protection equipment. Although copper wire separator of different factories have their own structure and style, they are generally divided into two kinds, wet-type and dry-type.

Wet separation is a traditional method, of which the idea is coming from mineral select. Since it needs water in the process of production, it will cause little pollution. Although it has relatively applied range, it does not represent the future trend. Compared with wet-type copper wire separator, the dry-type has many advantages:

Wet separation is a traditional method, of which the idea is coming from mineral select. Since it needs water in the process of production, it will cause little pollution. Although it has relatively applied range, it does not represent the future trend. Compared with wet-type copper wire separator, the dry-type has many advantages:

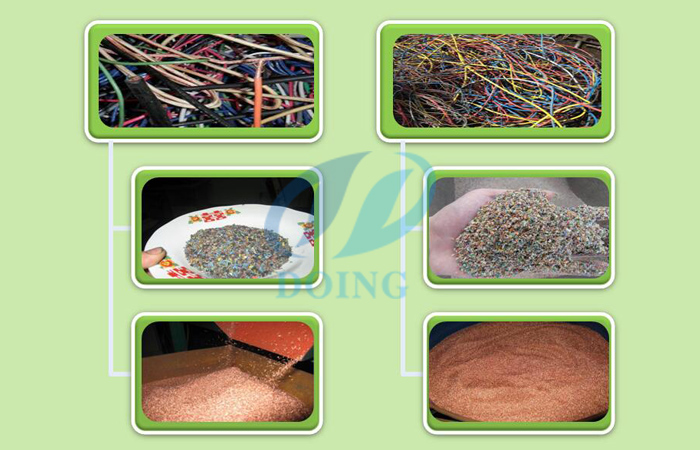

Copper wire separator final product

1) Less energy consumption. Every ambitious businessman wants to expand his business within the energy consumption under control. If you use wet-type copper wire separator, many problems will be out of your control. For example, a large amount of water taking part in process of production not only increases the energy consumption, but also adds the cost of production. Apart from these questions, you have to expend extra money to deal with waste water. But if you employ dry-type, you will not face any of these questions.

2) Easy operation. Since the dry-type does not need water, it simplifies the operating process, which makes it easy for the operator to acquire. Besides, many new technologies are applied to dry-type copper cable granulator, including PLC control system; hence it undoubtedly brings more operating convenience for our customers.

3) Environmental protection. The dry-type mainly adopts more eco-friendly methods to separate, such as air filters or static. The general process is: crushing---sorting with air filters--collecting dust. Therefore, the dry-type produces no dust and environmental pollution. For this reason, many manufactures focus on the production and research of dry-type copper wire separator.

4) Strong adaptive capacity. As we know, water is becoming more and more precious and many countries and regions face the shortage of water, saving water in the process of production must be included into our consideration. Dry-type undoubtedly is fit-for-purpose. You can use it without any geographical restrictions

Leave Message

Please kindly leave your requirements in detail, or contact us via +86 15037138562. Our professional sales manager will contact you within 24 hours. Your contact information will be protected.

- QWhat machine do you want to learn about?

- Solar Panel Recycling Machine

- Lithium Battery Recycling Machine

- E-waste PCB Recycling Machine

- Copper Wire Recycling Machine

- Carbonization Pyrolysis Machine

- Radiator Recycling Machine

- Aluminum Plastic Recycling Machine

- Other:

- QWhat raw material do you want to process?

- Bamboo

- Wood

- Sawdust

- Coconut shell

- Palm Kernel Shell

- Wood Chips

- Not decided yet

- Other:

- QMachine processing capacity (tons of feedstock)

- Other:

- Not decided yet

- QWhat final product do you mainly want to obtain? For what applications?