Copper wire stripping machine

Copper alloys scrap or copper scrap is generated during metal product fabrication or when a copper-containing product reaches its end of life. As for copper scrap origin, there are two types of copper scrap: new scrap and old scrap. New scrap is generated during the initial manufacturing process, originating from factories that produce articles from copper or copper alloys. Old scrap is collected after a consumer cycle, either separated or mixed and it is often contaminated to a certain degree, depending highly on origin and collection systems.

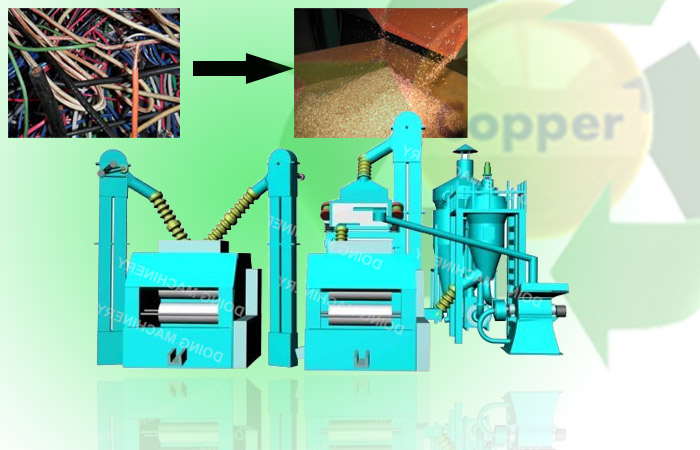

In developed countries, the predominant way of recycling the mental from cable scrap is automated cable chopping according to BIR. The process often includes pre-sorting, cable chopping, granulating, screening and density separating. The metal content of residue streams can vary from less than 1% to more than 15%. If a dry electrostatic system or wet separation (e.g. cyclones, tables) is used, the metal content may be reduced to less than 0.1%, which will consequently increase the value of the recovered plastic. In general, the overall metal recovery is around 94-99%.

An environmental-protection and less costly way for material separation is copper wire stripping . Copper wire stripping machine is widely used in most developed countries by utilities, cable manufacturers, cable chopping companies and metal scrap dealers. In contrast to chopping, the greatest advantage of stripping is the high purity of the recycled metal and insulation materials.

Leave Message

Please kindly leave your requirements in detail, or contact us via +86 15037138562. Our professional sales manager will contact you within 24 hours. Your contact information will be protected.

- QWhat machine do you want to learn about?

- Solar Panel Recycling Machine

- Lithium Battery Recycling Machine

- E-waste PCB Recycling Machine

- Copper Wire Recycling Machine

- Carbonization Pyrolysis Machine

- Radiator Recycling Machine

- Aluminum Plastic Recycling Machine

- Other:

- QWhat raw material do you want to process?

- Bamboo

- Wood

- Sawdust

- Coconut shell

- Palm Kernel Shell

- Wood Chips

- Not decided yet

- Other:

- QMachine processing capacity (tons of feedstock)

- Other:

- Not decided yet

- QWhat final product do you mainly want to obtain? For what applications?