Electronics waste mainly refers to all kinds of circuit board, copper-clad board, computer board, TV board, printed circuit board, various of waste computer board and processing waste, etc. It consists of plastic, glass, metal and whatsoever. And the main components of electronics waste are Cu 20%, Fe 8%, Sn 4%, Ni 2%, Pb 2%, Al 2%, ZN 1%, SB 0.4%, Au 1000g/t, Pd 50g/t and other substance. Obviously, electronics waste contains a great amount of resources.

Main components of electronic waste

According to the report, the world produces 30-40 million tons of electronics waste every year, and the annual growth rate is 6%, which is six times faster than the growth rate of total waste, making it the fastest growing waste in the world. This has posed a great threat to the global ecological environment and become a problem of global sustainable development. So it is a urgent thing that find good electronics waste management solution.

If you has some electronics waste, maybe you can sell them to the recycle plant, or put them into the corresponding trash cans for recycling personnel to process. However, if you want to process electronics waste in quantity, at present, there are two main electronics waste management solutions: heat treatment technology and mechanical treatment.

1.Heat treatment technology

Pyrolysis technology uses anoxic or anaerobic conditions to decompose organic matter into gas, oil, or glue to separate it from the metal. Components are removed from the e-waste, and the sheets are crushed and fed into a reactor to decompose. Polymer materials such as epoxy resin are heated to a certain temperature under inert gas to generate low molecular weight substances. Condense the pyrolysis oil and gas from the reactor to obtain non-condensable gas and liquid pyrolysis oil. Metal and glass fiber and other components basically do not change their properties and remain in the reactor as solid residue, which can be separated and recycled by simple physical methods.

Continuous pyrolysis plant

Continuous pyrolysis plant

Pyrolysis technology not only avoids the complex separation process of metal and polymer materials, but also can recover heat and chemical materials from pyrolysis products, with little environmental pollution and extremely attractive. However, the process of this technology is complicated and has not been applied in industry.

2.Mechanical treatment

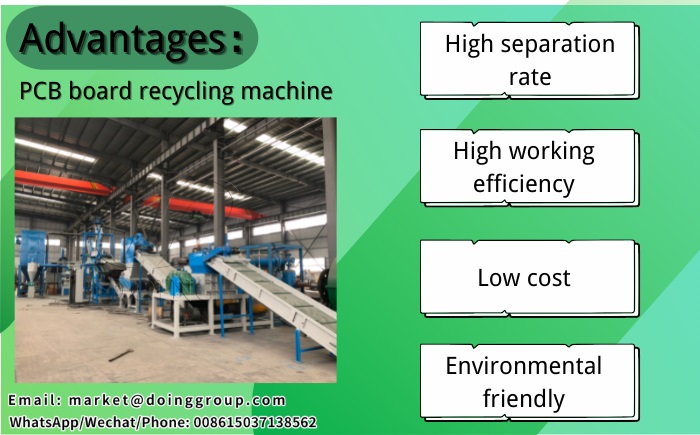

Mechanical treatment is an effective method to process electronics waste to realize its different components and separation. The machine used is called PCB board recycling machine, and the process of it is generally divided into disassembly, crushing and sorting three steps.

PCB board recycling machine

PCB board recycling machine

First of all, the components on the waste circuit board are disassembled, and the disassembled plate is broken into 20-30 mm particles in the shredder and crusher. After that, these particles are transported into the airflow specific gravity separator and electrostatic separator through negative pressure, and the metal and resin are separated by different specific gravity and metal conductivity. The separation rate of this method to separate mix metal and resins is up to 99%. The most important is that this method would not cause any resources waste and environmental problems.

In addition, mechanical treatment of electronic waste can be divided into dry method and wet method according to different treatment processes. Dry recycling does not have to consider the drying and sludge disposal of products, products meet the needs of the market, is a more widely studied and applied technical method. So Doing's PCB board recycling machine adopts dry and physical separation, which can help customers to get high quality metals and resin fiber.

It is understood that the market price of copper can reach 6000$/ton, the market price of iron can reach 1917$ /ton, and the market price of plastic can reach 589$/ton, with high economic value.

PCB board recycling machine

PCB board recycling machine

Obviously, using PCB board recycling machine to manage electronics waste is a good solution. It will be no fire, no chemical, no secondary waste, total friendly to the environment. Over the years, Doing Company adheres to the "quality first, integrity first" business philosophy, for the majority of users to provide the best pre-sale and after-sales service, the most professional technical support, strict quality control. We are looking forwad to have a cooperation with you!

Leave Message

Please kindly leave your requirements in detail, or contact us via +86 15037138562. Our professional sales manager will contact you within 24 hours. Your contact information will be protected.

- QWhat machine do you want to learn about?

- Solar Panel Recycling Machine

- Lithium Battery Recycling Machine

- E-waste PCB Recycling Machine

- Copper Wire Recycling Machine

- Carbonization Pyrolysis Machine

- Radiator Recycling Machine

- Aluminum Plastic Recycling Machine

- Other:

- QWhat raw material do you want to process?

- Bamboo

- Wood

- Sawdust

- Coconut shell

- Palm Kernel Shell

- Wood Chips

- Not decided yet

- Other:

- QMachine processing capacity (tons of feedstock)

- Other:

- Not decided yet

- QWhat final product do you mainly want to obtain? For what applications?