Four frequently asked questions about buying a E waste PCB board recycling machine

Editor: Henan Doing

Date:June 29, 2023

Recycling waste electronic boards are becoming increasingly popular as more people are becoming aware of the importance of environmental protection. Some machines were produced to solve negative impact of electronic waste boards. E waste PCB board machines are specially designed to recycle printed circuit boards (PCBs), which are commonly found in rapidly updated electronic devices such as computers, televisions, and mobile phones, ect.

However, buying a E waste PCB board recycling machine can be a daunting task, especially if you are facing many types and models. In this article, we will discuss four frequently asked questions about buying E waste PCB board recycling machines.

1)The capacity of E waste PCB board recycling machine

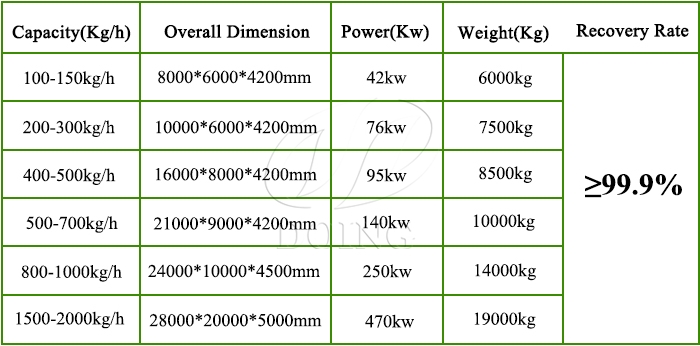

The capacity of the E waste PCB board recycling machine is important because it determines how much PCB boards you can process at a time. The conventional processing capacity of our machine is 200-2000KG/h, depending on your needs. If your business scale is small, choosing a processing capacity of 200-300kg/h is preferred. Conversely, if your business scale is large and you need to process more waste boards, choosing a larger processing capacity can improve processing efficiency and reduce consumption. Actually, the capacity of E waste PCB board recycling machine need to match the capacity of your raw materials and funds. Buying a proper E waste PCB board recycling machine is not a easy thing, but we provide sincere guidance according to your actual situation.

The capacity of E waste PCB board recycling machine

The capacity of E waste PCB board recycling machine

2)The type of E waste PCB board recycling machine

In terms of processing methods, the types of E waste PCB board recycling machine on the market mainly include chemical machines and physical machines, both of which have a high separation rate and efficiency. However, the physical e waste PCB board recycling machine is much better than chemical machine. For chemical E waste PCB board recycling machine, you should have relatively adequate budget, strict operating procedures and safety measures because of dangerous chemicals and the retreatment of wastewater.

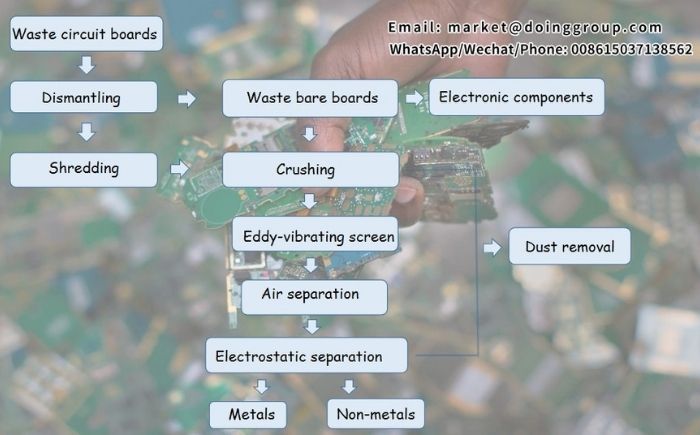

The physical E waste PCB board recycling machine mainly processes waste electronic boards through physical methods such as crushing, screening, and separation, and separates the precious mixed metal and non-metallic materials on the waste board. Physical E waste PCB board recycling machine is relatively safer and easy to operate, even does not produce secondary pollution.

E waste PCB board recycling machine

E waste PCB board recycling machine

In terms of the degree of automation, physical E waste PCB board recycling machines include manual machines, semi-automatic machines, and fully automatic machines. Manual machines require the operator to feed the PCBs into the machine by hand, while semi-automatic machines use a conveyor belt to feed the PCBs into the machine. Fully automatic machines are the most advanced and require no operator intervention. They use sensors and computer controls to automatically feed the PCBs into the machine and separate the metals from the waste electronic boards. However, this fully automatic machine is very expensive and suitable for a large and steady supply of waste electronic boards.

3)The quality of E waste PCB board recycling machine

There are many factors that affect the quality of a machine, including design, material quality, manufacturing process, inspection and testing, maintenance and care, etc. Among them, the design is the most important factor affecting the quality of the machine, because a good design can ensure the normal operation of the machine during use and has a long service life. Due to limited technology, different manufacturers have different designs. The quality of machine from hundreds of manufacturers is difficult to distinguish between good and bad. But it is a wise choice that buy machines from big manufacturers. They not only have more mature and professional techniques, but also provide perfect after-sales service.

The working process of E waste PCB board recycling machine

The working process of E waste PCB board recycling machine

Henan Doing Company is specialized in waste recycling machine more than twelve years, we have own high qualified engineer team. Our machines not only have good welding process, but also choose machine parts with high precision, high strength and high wear resistance. We are convinced that a good E waste PCB board machine should have the characteristics of high precision, high stability, low error, easy operation, stable and reliable. For example, most of the machine on the market is 55CrSi. But 55CrSi is mainly used to tear wood and plastic. H13 is the main tool for tearing steel. Generally, blades of this material can be used for 2-3 years. The better blades include D2 and LD, whose cost will be higher. Of course, if you have a request, we can customize it for you.

4)The price of E waste PCB board recycling machine

The prices vary according to different processing capacity and configurations. In addition, in order to meet some customers' special requirements, such as blade material, processing capacity and some optional configurations, the price of customized machines will be higher. For common configurations of E waste PCB board recycling machine, we have capacities range from 100kg/h to 2T/H, with prices range from USD11000 to USD195000.

Project cases of E waste PCB board recycling machine

Project cases of E waste PCB board recycling machine

For more in-depth knowledge about the E waste PCB board recycling machine, don't hesitate to reach out to us.

Leave Message

Please kindly leave your requirements in detail, or contact us via +86 15037138562. Our professional sales manager will contact you within 24 hours. Your contact information will be protected.

- QWhat machine do you want to learn about?

- Solar Panel Recycling Machine

- Lithium Battery Recycling Machine

- E-waste PCB Recycling Machine

- Copper Wire Recycling Machine

- Carbonization Pyrolysis Machine

- Radiator Recycling Machine

- Aluminum Plastic Recycling Machine

- Other:

- QWhat raw material do you want to process?

- Bamboo

- Wood

- Sawdust

- Coconut shell

- Palm Kernel Shell

- Wood Chips

- Not decided yet

- Other:

- QMachine processing capacity (tons of feedstock)

- Other:

- Not decided yet

- QWhat final product do you mainly want to obtain? For what applications?