How to get aluminum out of aluminum plastic composite panel?

Editor: Henan Doing

Date:August 19, 2021

As a new type of decorative material, aluminum plastic composite panel (also known as aluminum-plastic panel) is quickly favored by people for its excellent processing performance and fire resistance. However, they will also cause some waste problems when they became waste. Due to the aluminum plastic composite panel usually consists of aluminum and plastic, so we can separate and recycle aluminum, turning these waste aluminum plastic composite panel into treasure.

Aluminum plastic recycling machine

Aluminum plastic recycling machine

Well, as we know, the aluminum has good adhesion with plastic, which is hard to separate. So how to get aluminum out of aluminum plastic composite panel becomes to be a hard problem. To solve this problem, Henan Doing Holdings designed a machine to separate aluminum from aluminum plastic composite panel, called aluminum plastic recycling machine. It can separate aluminum and plastic from the aluminum plastic composite panel. Aluminum plastic recycling machine can not only process aluminum plastic composite panel, but also aluminum plastic composite foil and medical blister packs.

Aluminum plastic recycling process

Aluminum plastic recycling process

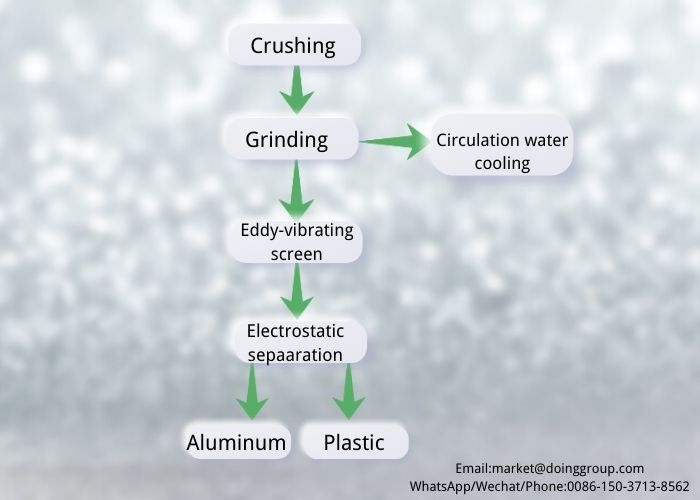

The working process of aluminum plastic recycling machine is very easy, which is as follows:

1. Crushing - Crusher will crush these aluminum plastic composite panel into small pieces;

2. Grinding - Grinding mill will grind these small pieces into powder, which can make it easy to separate aluminum and plastic;

3. Sieving - Eddy-vibrating screen will check the size of powder, and it will send these bigger powder back to the grinding mill to further grinding, until completely ground;

4. Electrostatic separation - Electrostatic separator will separate aluminum and plastic according to the different conductivities of aluminum and plastic.

Aluminum plastic recycling machine and the products

Aluminum plastic recycling machine and the products

One thing to note, grinding will cause high temperature, which will burn materials and cause adhesion, so the recovery rate will get low. Aluminum Plastic recycling machine is equipped with a circulation water cooling system to reduce the temperature of the grinding powder, which can make the recovery rate reach to 100%.

It is worth mentioning that the separate rate is pretty high, which is 99%. Besides, aluminum plastic recycling machine adopts dry type physical separation method, which doesn't use fire, water or chemical and other factors that may affect the environment. It is an environmental protection machine. If you want to purchase a machine with high separation rate and environmental protection, welcome to contact us.

Leave Message

Please kindly leave your requirements in detail, or contact us via +86 15037138562. Our professional sales manager will contact you within 24 hours. Your contact information will be protected.

- QWhat machine do you want to learn about?

- Solar Panel Recycling Machine

- Lithium Battery Recycling Machine

- E-waste PCB Recycling Machine

- Copper Wire Recycling Machine

- Carbonization Pyrolysis Machine

- Radiator Recycling Machine

- Aluminum Plastic Recycling Machine

- Other:

- QWhat raw material do you want to process?

- Bamboo

- Wood

- Sawdust

- Coconut shell

- Palm Kernel Shell

- Wood Chips

- Not decided yet

- Other:

- QMachine processing capacity (tons of feedstock)

- Other:

- Not decided yet

- QWhat final product do you mainly want to obtain? For what applications?