Scrap copper wire is made of copper and plastic, which can be separated and reproduced new products. The effective separation of copper and plastic has always been a top priority in the later stage of the scrap copper wire recovery. At present, there are three main separation methods to separate copper and plastic from scrap copper wire: fire burning, chemical dissolution and dry physical separation.

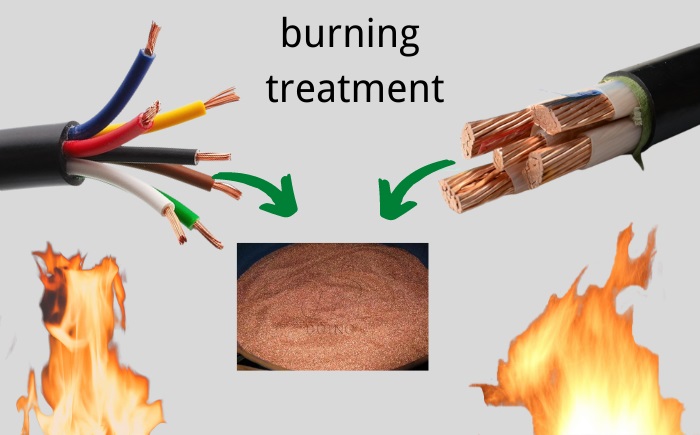

Fire burning:

Fire burning is a method for easily disposal for scrap copper wire, which takes advantage of the flammability of scrap copper wire. Through burning, the plastic of the outer layer of scrap copper wire will be melted, and the remaining metal is the non-flammable metal - copper.

Fire burning

Fire burning

Fire burning can separate copper and plastic from scrap copper wire with a simple and fast way. However, during burning, the melted plastic will stick to copper, which will cause low separation rate and recovery rate of copper. Besides, it will produce a large amount of gas, which has severe pollution to environment.

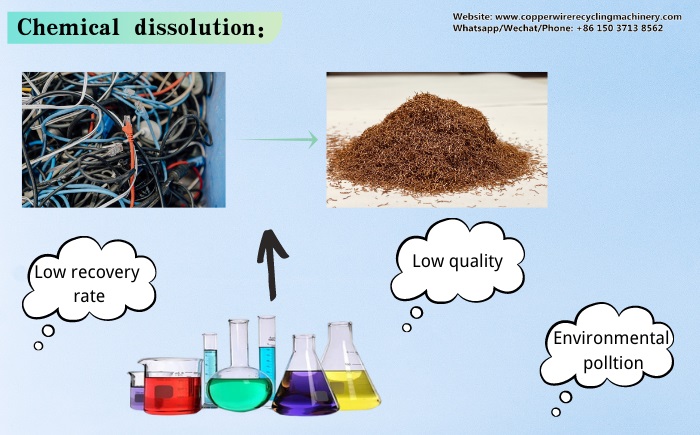

Chemical dissolution:

Chemical dissolution is chemical method, which will use chemical dissolution to process scrap copper wire to separate copper and plastic. Immerse the scrap copper wire in water with chemical solvent, and just left for 1-2 hours, the copper will be extracted naturally.

Chemical dissolution

Chemical dissolution

Just like fire burning, this method can also separate copper from plastic fast and simple. But the recovery rate is relatively inefficient, and to some extent, the quality of copper will also be affected due to the chemical solvent, which won't be sold a good price in metal trading market. In addition, the used water with chemical solvent is usually dumped directly, which will cause pollution to soil and water.

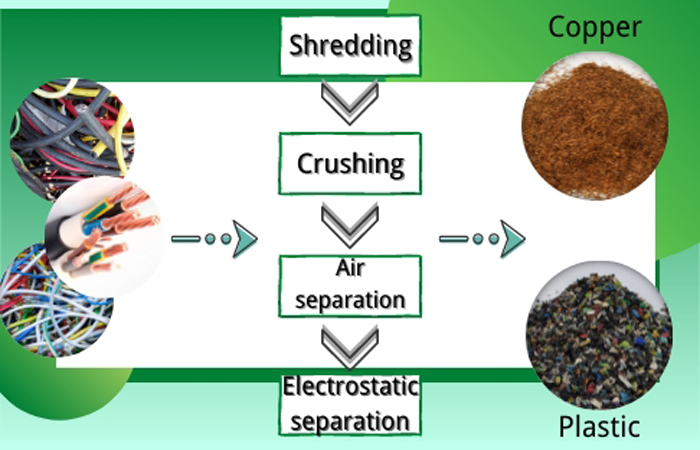

Dry physical separation:

Dry physical separation usually refers to process scrap copper wire by using scrap copper wire recycling machine, which is an environmental friendly and high efficient way to separate copper and plastic from scrap copper wire. The whole scrap cable wire recycling machine includes crushing, air separation and electrostatic separation.

Scrap copper wire recycling machine

Scrap copper wire recycling machine

First, the scrap cable wires is pressed into small pieces so that it can be separated in the air separator because of the difference in gravity between copper and plastic. And if the raw material has very thin wires, the separation rate may not be so ideal, so electrostatic separation is required. Electrostatic separator can separate fine copper from plastic according to their different conductivity.

The working process of scrap copper wire recycling machine uses no water, fire, or chemical solvent, and the dust removal system ensures that no dust is flying during operation, thus it won't lead to any pollution to environment. Moreover, the separated copper and plastic have high quality, which have a considerable price.

The following is a profit analysis table of scrap copper wire recycling machine provided by our Indian customer, which can be used as a reference.

| Running cost / Day | |||||

| Item | Input | Quantity | Price | Input cost | Total cost |

| 1 | Scrap car wires | 500kg/h * 8h = 4T | USD3355 / ton | USD13420 | USD13522 |

| 2 | Power consumption | 65Kw/H * 8H = 520KwH | USD0.1/ KWH | USD52 | |

| 3 | Workers | 2 workers | USD25per one | USD50 | |

| Income / Day | |||||

| Item | Output | Quantity | Price | Income | Total income |

| 1 | Copper | 4T *55%= 2.2T | USD9422/ ton | USD20728.4 | USD 20953.4 |

| 2 | Plastic | 1.8T | USD125/ ton | USD225 | |

| Daily Profit = USD 20953.4– USD 13522 = USD 7431.4 | |||||

Tips: The price is different in different countries and areas. You can calculate your profit according to your local accurate price.

Henan Doing is a professional and experienced manufacturer of scrap copper wire recycling machine. If you want to separate copper and plastic from scrap copper wire by scrap copper wire recycling machine, welcome to contact us.

Leave Message

Please kindly leave your requirements in detail, or contact us via +86 15037138562. Our professional sales manager will contact you within 24 hours. Your contact information will be protected.

- QWhat machine do you want to learn about?

- Solar Panel Recycling Machine

- Lithium Battery Recycling Machine

- E-waste PCB Recycling Machine

- Copper Wire Recycling Machine

- Carbonization Pyrolysis Machine

- Radiator Recycling Machine

- Aluminum Plastic Recycling Machine

- Other:

- QWhat raw material do you want to process?

- Bamboo

- Wood

- Sawdust

- Coconut shell

- Palm Kernel Shell

- Wood Chips

- Not decided yet

- Other:

- QMachine processing capacity (tons of feedstock)

- Other:

- Not decided yet

- QWhat final product do you mainly want to obtain? For what applications?