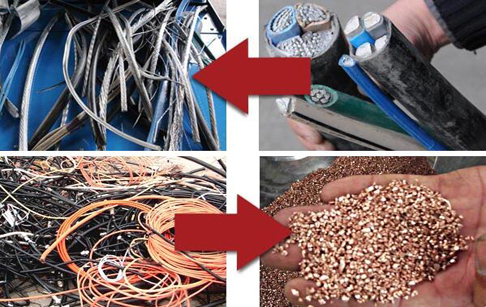

Copper has a high stability, so it has a very wide range of use, compared to mining new copper, for the recycling of waste copper wire, it is more economically viable and cost-effective! ! So how do you separate the collected scrap copper into plastic and pass?

Scrap copper wire

DoingGroup manufactures environmentally-friendly cable and wire recycling equipment for waste scraps, scrapped copper-plastic wires, fine yarns, copper-plastic composite wires, aluminum-plastic wires, and sheath wires, with coarse crushing, iron removal, fine crushing, and specific gravity. Selection, electrostatic separation process, complete dry physical separation, to achieve the dual recovery of plastics and metals, comprehensive utilization.

Structural features:

Scrap copper wire recycling machine

1.Integrated structure design, compact structure, small footprint, easy to move, can be produced by putting it on the flat ground and turning on the power.

2. Using PLC control, simple and beautiful appearance, simple operation, an operator can produce.

3. Gravity sorting As an important part of the separation of copper and plastic and plastics, the Italian air suspension sorting process is adopted. The vibration frequency and the material suspension air supply device can be accurately adjusted according to different materials.

4. The crushing system uses SKD-11 alloy cutting tools, processing hardness reaches HR58 degrees, and can guarantee the certain toughness of the crushing blade under the condition of ensuring high wear resistance. The structure design is a figure-eight alternating shear structure, and the wire crushing equipment shell The use of a water-cooled system eliminates the need for long-term production of heat-melting materials.

5. The whole set of equipment is fully enclosed and equipped with an advanced pulse dust removal system, which effectively collects dust from the production process and discharges it from the dust discharge outlet.

6. According to the copper and wire functions produced in various countries, copper with a purity of more than 99.5% is recovered, but there will be 3-5% copper powder and wool copper will be lost to the plastic along with the separation process. Our company is equipped with The electrostatic selection equipment sorts the remaining copper in the plastic again, so that no plastic can be seen in the copper, and the effect of copper cannot be seen in the plastic.

DoingGroup provides large, medium and small scrap copper recycling machine to meet customers' different production needs.

Leave Message

Please kindly leave your requirements in detail, or contact us via +86 15037138562. Our professional sales manager will contact you within 24 hours. Your contact information will be protected.

- QWhat machine do you want to learn about?

- Solar Panel Recycling Machine

- Lithium Battery Recycling Machine

- E-waste PCB Recycling Machine

- Copper Wire Recycling Machine

- Carbonization Pyrolysis Machine

- Radiator Recycling Machine

- Aluminum Plastic Recycling Machine

- Other:

- QWhat raw material do you want to process?

- Bamboo

- Wood

- Sawdust

- Coconut shell

- Palm Kernel Shell

- Wood Chips

- Not decided yet

- Other:

- QMachine processing capacity (tons of feedstock)

- Other:

- Not decided yet

- QWhat final product do you mainly want to obtain? For what applications?