What’s the use of copper and plastic separated from waste cable wires?

Editor: Henan Doing

Date:March 12, 2022

Most waste cable wires are made of copper and plastic, the rest are made of aluminum and plastic. Most of people know that we can recycle copper and plastic from waste cable. But there are little people know that the use of copper and plastic. In this article, I will tell you the use of copper and plastic separated from waste cable wires.

Copper uses

Copper uses

For the copper, it can be sold directly to the person who collects copper granulator or the person who does metal recovery for money. If the quantity of copper is large, you can sell them directly to the copper electrolytic plant (copper factory).

Plastic uses

Plastic uses

For the plastic, you can sell it to the people who collect plastic. The plastic can be pelleted to make new plastic products, like rubber mattress, insoles, even wire cover etc.

At the stage, with the industrial recovery, there are a lot of demand of copper in the market. And with the copper demand increase, the copper price is also has a big increase. From a long-term development perspective, copper wire recycling can not only protect the environment but also can make profits, it’s really a potential business.

Working process of copper wire granulator machine

Working process of copper wire granulator machine

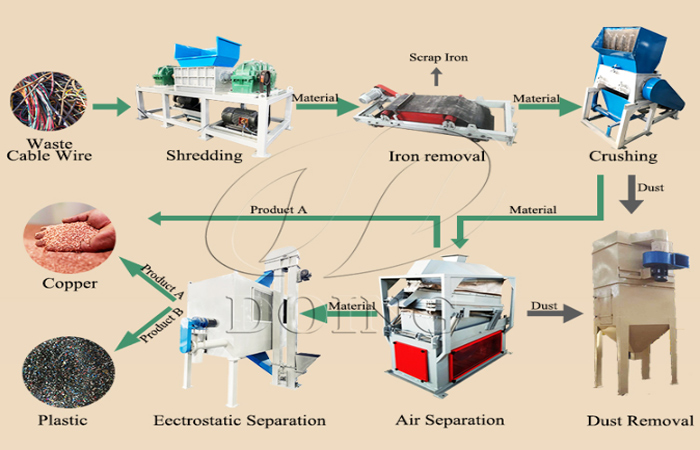

As for the waste cable wire recycling business's profit, it is effected by the purity and quality of copper and plastic. As long as we get high purity and good quality of copper and plastic, we can get high profit. There are many ways to process waste cable wires, but the best way is to use copper wire granulator machine, which is specialized to process cable wires by crushing and separating, to get high purity and good quality copper and plastic.

If you are interested in copper wire recycling business, welcome to contact us to get copper wire granulator machine to help you get high profit.

Leave Message

Please kindly leave your requirements in detail, or contact us via +86 15037138562. Our professional sales manager will contact you within 24 hours. Your contact information will be protected.

- QWhat machine do you want to learn about?

- Solar Panel Recycling Machine

- Lithium Battery Recycling Machine

- E-waste PCB Recycling Machine

- Copper Wire Recycling Machine

- Carbonization Pyrolysis Machine

- Radiator Recycling Machine

- Aluminum Plastic Recycling Machine

- Other:

- QWhat raw material do you want to process?

- Bamboo

- Wood

- Sawdust

- Coconut shell

- Palm Kernel Shell

- Wood Chips

- Not decided yet

- Other:

- QMachine processing capacity (tons of feedstock)

- Other:

- Not decided yet

- QWhat final product do you mainly want to obtain? For what applications?