1. What’s used copper wire granulators?

DOING company used copper wire granulators which is used for separate copper and plastics from scrap copper cable. Because the separated copper and plastics like rice grain, so here call granulator. And get the copper can be recycled and reused. Then DOING used copper wire granulators is one kind of environmental protection equipment.

Used copper wire granulators

Used copper wire granulators

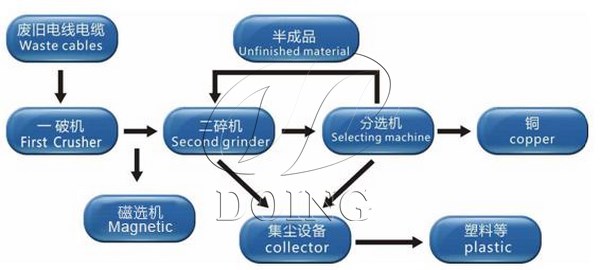

2. What’s the working process of theused copper wire granulators?

Step 1: Crushing: Use DOING Wire crusher (grinder) to cut the whole wire into uniform particles (Diameter at 0.67-1mm). In the crusher of used copper wire granulators, a certain number of moving knives are welded on the crusher shaft, and a certain number of fixed knives are welded on the crusher shell around the shaft. The moving knife rotates with the rotation of the crusher shaft and interacts with the fixed knife to form a shear force similar to the scissors, which can cut the wire. The bottom of the crusher is equipped with screen mesh, and the wire must be cut to the specified size before it enters the air separator.

Step 2: Air separation: The lower part of the air separator is provided with a fan. Plastic particles with smaller density are sucked up and moved to the plastic outlet of the air separator under the vibration of the air separator. Because of the high density of copper particles, they cannot be sucked up by the wind. Under the action of vibration, these copper meters move to the copper outlet of the air separator.

Step 3: If here the copper wire with a great variety and have more diameter less than 3mm, better here add one electrostatic separation machine to separate the smaller particles and low density copper scale. Because when the wire is cut in the crusher, it will inevitably produce a certain amount of copper powder (about 2%). Because of its small mass, these copper powder will be mixed in the plastic particles. Electrostatic separation machine will be added to screen the plastic again, and these copper powder can be selected.

Step 4: If here much of the copper wire diameter at 20-80mm, advice to increase one Shredder to rend the bulk of the wire into about 3-5CM segments, and then enter the used copper wire granulators . This way not only avoid the blockage of large groups of wires, but also significantly improve the working efficiency of the used copper wire granulators.

The working process of theused copper wire granulators

The working process of theused copper wire granulators

3. What kind of effect can be achieved from the used copper wire granulators?

The recovery rate of used copper wire granulators is about 95-98%, basically actualize the recovery and reuse of high purity copper. No dust and secondary pollution, protecting the environment; Integrating various advanced technologies, reduces human-based costs, improves production efficiency, and has high economic benefits.

Leave Message

Please kindly leave your requirements in detail, or contact us via +86 15037138562. Our professional sales manager will contact you within 24 hours. Your contact information will be protected.

- QWhat machine do you want to learn about?

- Solar Panel Recycling Machine

- Lithium Battery Recycling Machine

- E-waste PCB Recycling Machine

- Copper Wire Recycling Machine

- Carbonization Pyrolysis Machine

- Radiator Recycling Machine

- Aluminum Plastic Recycling Machine

- Other:

- QWhat raw material do you want to process?

- Bamboo

- Wood

- Sawdust

- Coconut shell

- Palm Kernel Shell

- Wood Chips

- Not decided yet

- Other:

- QMachine processing capacity (tons of feedstock)

- Other:

- Not decided yet

- QWhat final product do you mainly want to obtain? For what applications?