With the increase of awareness of environmental protection, people are not throw away scrap wire directly anymore, instead of trying their best to recycle them. In generally, there are many ways to recycle waste copper wire, such as fire burning, chemical reagent melting, manual stripping, recycling by machine and so on. But the fact declared that the way of recycling by machine may be the best way to recycle waste copper wire. Because it is the most environmental friendly, highest separation rate and highest economic benefit way. In the next article, I will elaborate for you one by one take the copper wire recycling machine for example.

1. Most environmental friendly

The whole working process of copper wire recycling machine adopts dry type separation method, which is not similar with fire burning or chemical reagent melting. It will not produce waste water, smoke or toxic chemicals. So it will not do harm to environment. Besides, it will not produce dust to the environment, because it is equipped a pulse dust removal system, which is used to collect the dust during the process.

the environmental feature of copper wire recycling machine

the environmental feature of copper wire recycling machine

2. Highest separation rate

Copper wire recycling machine can separate copper and plastic through crushing and separating. The crusher can crush copper wire into small particles. The these particles will be sent to an electrostatic separator. The electrostatic will separate them clearly according the different conductivities of metal and non-metal. The separation rate can reach to 99%, which is beyond the reach of fire burning, chemical reagent melting and manual stripping.

copper wire recycling machine

copper wire recycling machine

3.Highest economic benefit

Compared to fire burning, chemical melting and manual stripping, the copper separated by copper wire recycling machine has higher quality and purity. So the price is pretty high. Copper wire recycling machine can bring you highest economic benefit.

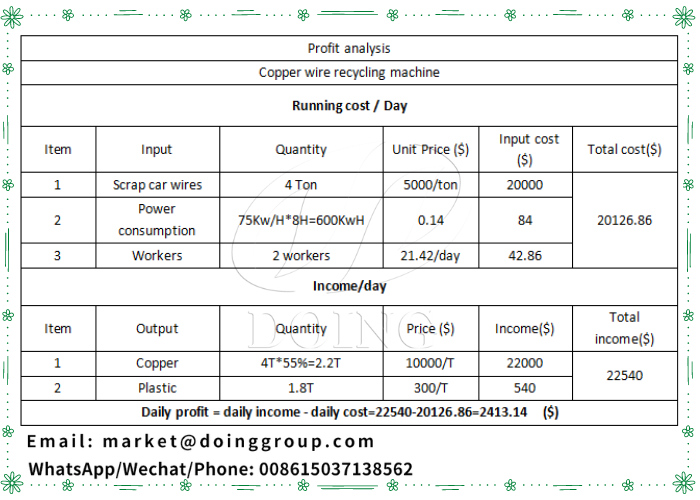

In below table, we take the automobile wire whose copper content is around 55% as example. And we use one set copper wire recycling machine with the processing capacity of 500kg/h and the power consumption is 75KW/H. This machine just need 2 workers to operate.

The selling price for copper is around $10000/T and $300/T for plastic.

If working 8 hours per day, copper wire recycling machine can recycle 4 tons waste car wires. We can get 2.2T copper and 1.8T plastic. After calculating, The total cost per day is $20126.86, and total income is $22540, so the profit per day is $2413.14.

Profit analysis

copper wire recycling machine analysis profit table

copper wire recycling machine analysis profit table

Due to the changeable of market price, this table is just as for a reference.

Above these three advantages just are some main advantages of copper wire recycling machine, it also has other advantages, like high working efficiency, small footprint and so on. So if you want one and multiple advantages in one machine, welcome to contact us-Henan Doing Environmental Protection Technology Co., Ltd.

Leave Message

Please kindly leave your requirements in detail, or contact us via +86 15037138562. Our professional sales manager will contact you within 24 hours. Your contact information will be protected.

- QWhat machine do you want to learn about?

- Solar Panel Recycling Machine

- Lithium Battery Recycling Machine

- E-waste PCB Recycling Machine

- Copper Wire Recycling Machine

- Carbonization Pyrolysis Machine

- Radiator Recycling Machine

- Aluminum Plastic Recycling Machine

- Other:

- QWhat raw material do you want to process?

- Bamboo

- Wood

- Sawdust

- Coconut shell

- Palm Kernel Shell

- Wood Chips

- Not decided yet

- Other:

- QMachine processing capacity (tons of feedstock)

- Other:

- Not decided yet

- QWhat final product do you mainly want to obtain? For what applications?