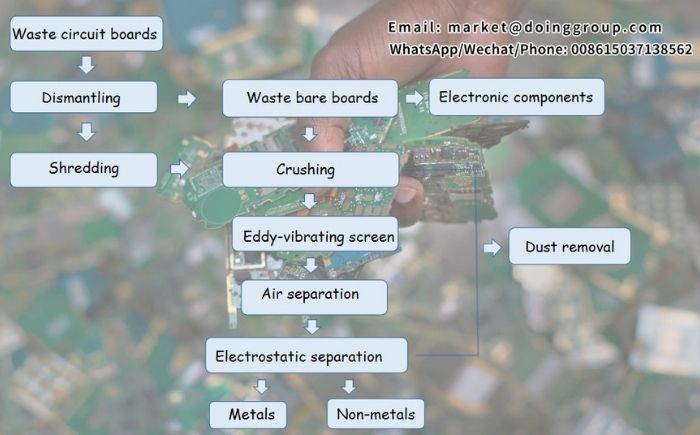

The raw materials are different, the process of PCB recycling machine is different, but the general process includes dismantling, shredding, crushing, sieving and separating. Through these steps, metals will be separated from resin fiber.

Process of PCB board recycling machine

Process of PCB board recycling machine

The process of PCB recycling machine adopts dry type crushing and separating method to separate mixed metals and resin fiber. First is crushing. First, shredder will shredding PCB circuit boards into small pieces which are 4mm. Second, the first and second crusher processes these mixed materials into 20 meshes size. And then, eddy vibrating screen will control the size of mixed materials and ensure all particles are less than 20 meshes. Finally, the electrostatic separator will separate metals from resin fiber according to the different conductivity of them.

PCB dismantling machine

PCB dismantling machine

However, the above process is mainly to process the bare boards. If the PCB circuit boards you processed is with electronic components, you should add a dismantling procedure before the above procedures. Using a PCB dismantling machine to dismantle the electronic components from the PCB boards. Then the bare boards will be separated into metals and resin fiber through shredding, crushing, sieving and separating. The separation rate can arrive to 99%.

In conclusion, this is the general working process of PCB board recycling machine. If you want to get detailed process of PCB recycling machine, we have many commissioning videos(PCB board recycling machine working process video) for watching. Welcome to contact us feel free.

Leave Message

Please kindly leave your requirements in detail, or contact us via +86 15037138562. Our professional sales manager will contact you within 24 hours. Your contact information will be protected.

- QWhat machine do you want to learn about?

- Solar Panel Recycling Machine

- Lithium Battery Recycling Machine

- E-waste PCB Recycling Machine

- Copper Wire Recycling Machine

- Carbonization Pyrolysis Machine

- Radiator Recycling Machine

- Aluminum Plastic Recycling Machine

- Other:

- QWhat raw material do you want to process?

- Bamboo

- Wood

- Sawdust

- Coconut shell

- Palm Kernel Shell

- Wood Chips

- Not decided yet

- Other:

- QMachine processing capacity (tons of feedstock)

- Other:

- Not decided yet

- QWhat final product do you mainly want to obtain? For what applications?