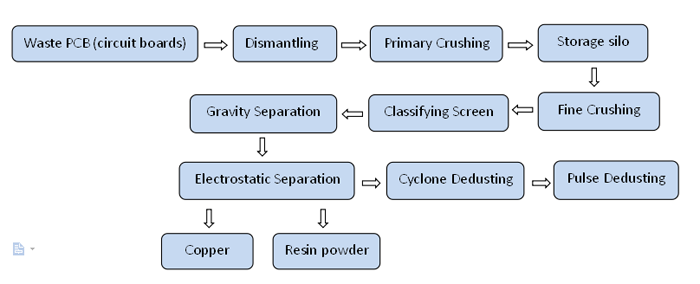

This type PCB board separation machine (high voltage electrostatic separation type) adopts a process route that makes raw materials such as printed circuit boards to be a mixture of metal and resin fiber powder by dry crushing and pulverization and then separates the metals from the non-metal materials such as resin by high voltage electrostatic separator. To avoid dust pollution in the process, the equipment also uses the three-in-one dust removal equipment. This dust removal equipment has three-stage dust removal: cyclone dust removal, bag dust removal and dust removal by air cleaner. All of these effectively solve the problem of dust pollution with every index up to the national standard.

This PCB board separation machine has a great capacity production and low consumption. And the copper purity of recycling is more than 99.99%.

PCB board separation machine

Application of PCB board separation machine

The PCB board separation machine can be used for recycling all kinds of circuit boards, computer board, TV board, aluminum-plastic plate, copper board, printed circuit boards etc. the metal recovery rate can be up to 99.9%.

| Model |

Power (kw) |

Capacity (Kg/h) |

Demission (mm) |

Efficiency separation |

Weight (kg) |

| DYPCB-300 | 80 | 300 | 8300*5300*4640 mm | 97-99% | 5000 |

| DYPCB-500 | 140 | 400-500 | 21200*4050*5420 mm | >99% | 17000 |

| DYPCB-800 | 185 | 700-800 | 26850*4050*5420 mm | >99% | 21000 |

| DYPCB-1000 | 255 | 900-1000 | 27000*5600*4750 mm | >99% | 25000 |

Flow diagram of PCB board separation machine

PCB board separation machine

Features of PCB board separation machine

1.New process of advanced mechanical pulverization and high voltage electrostatic separation is adopted so that the purity of metal and non-metal separated after crushing and dissociation is high.

2.The unit consumption of energy to treat one ton of waste and used printed circuit board is only about 3/5 of that of domestic product alike; the largest treatment capacity of one set of equipment is 1 ton per hour.

3.Low cost pcb milling machine has good comprehensive performance, having special effect on computer board, calculator board, TV board and other control printed circuit board, and compatibility for recovery of various circuit boards with capacitor components.

4.This PCB board separation machine is an upgraded and renewed product of wind-separated products, which consumes less power than wind-separated type and has no noise.

5.PCB board separation machine needs fewer operators and has no pollution and noise. Besides, the equipment is flexible for layout.

Leave Message

Please kindly leave your requirements in detail, or contact us via +86 15037138562. Our professional sales manager will contact you within 24 hours. Your contact information will be protected.

- QWhat machine do you want to learn about?

- Solar Panel Recycling Machine

- Lithium Battery Recycling Machine

- E-waste PCB Recycling Machine

- Copper Wire Recycling Machine

- Carbonization Pyrolysis Machine

- Radiator Recycling Machine

- Aluminum Plastic Recycling Machine

- Other:

- QWhat raw material do you want to process?

- Bamboo

- Wood

- Sawdust

- Coconut shell

- Palm Kernel Shell

- Wood Chips

- Not decided yet

- Other:

- QMachine processing capacity (tons of feedstock)

- Other:

- Not decided yet

- QWhat final product do you mainly want to obtain? For what applications?