Product Description:

Waste printed circuit board recycling machine

Waste printed circuit board recycling machine

Waste printed circuit board recycling machine is designed for processing all kinds of waste circuit boards to separate the precious metals and resin fiber, which is combined with the global advanced physical crushing and separating technology. Waste printed circuit board recycling machine's successfully developed, not only improves the recovery rate of metal, metal recovery rate is as high as 98%, but also prevents the environment being polluted, which is currently the best machine to recycle the waste printed circuit boards.

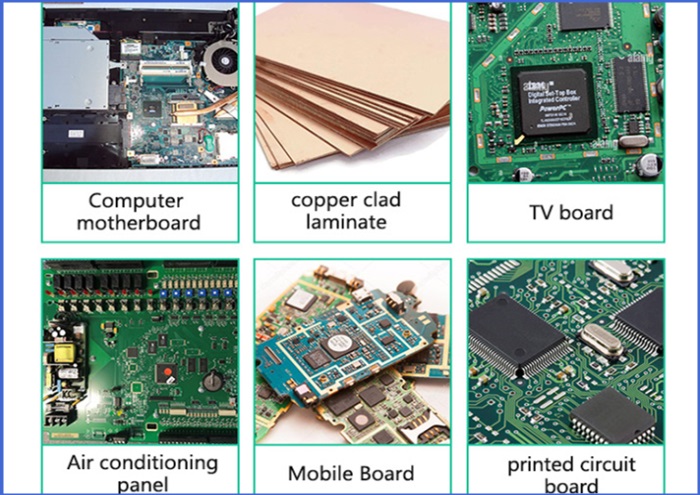

Raw Materials:

Various waste circuit boards

Various waste circuit boards

Waste printed circuit board recycling machine has excellent comprehensive performance and is suitable for all waste printed circuit boards, such as the computer boards, cell phone boards, TV boards, copper-clad laminate, and other household appliances, and the leftover of the separation of mixed metals and nonmetal materials.

Final products:

Final products and applications

Final products and applications

Because the printed circuit boards are made of metals and resin fiber, there is no doubt that the final product we get are precious metals(90% of copper) and resin fiber powder. Both metals and resin fiber have high value and wide application, which can help to change waste into treasure and bring great economic benefit.

Equipment Structure:

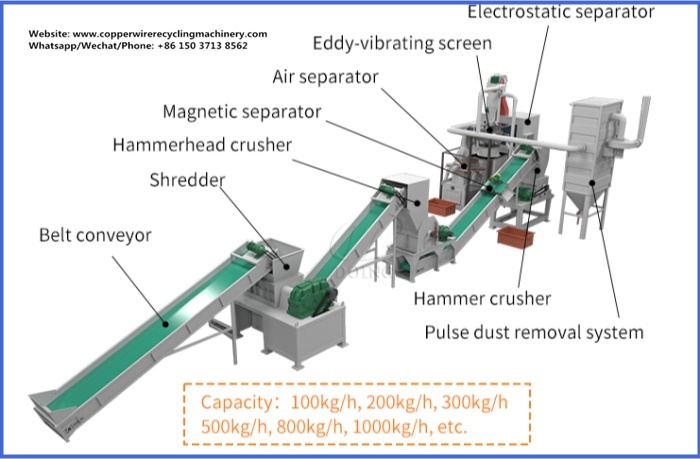

Equipment structure

Equipment structure

Waste printed circuit board recycling machine consists of shredding system(shredder), crushing system(crusher), sorting system(air separator and electrostatic separator) and dust collection system(pulse dust and cyclone dust collector). Besides, our waste printed circuit board recycling machine is controlled by PLC control system.

Related Machinery:

Electronic components dismantling machine

Electronic components dismantling machine

As we all known, there are some electronic components on the waste circuit boards, which are mainly resistor-capacitor with low value. To get more purer metals, it's better to remove the electronic components. Electronic components dismantling machine can disassemble the electronic components from circuit boards by melting tin at high temperatures.

Work Process:

Waste printed circuit board recycling machine adopts the shredding system and secondary crushing system to crush the waste circuit board into mixed powder (metal powder and resin fiber powder); And then through the air separator and electrostatic separator to separate metal powder and resin fiber powder out. To prevent the dust pollution during the working process, pulse dust and cyclone dust collector will effectively solve the dust pollution problem, with the collecting rate of 99.9%

Technical Parameters:

| Capacity(Kg/h) | Overall Dimension | Power(Kw) | Weight(Kg) | Recovery Rate |

| 100-150kg/h | 8000*6000*4200mm | 42kw | 6000kg | ≥99% |

| 200-300kg/h | 10000*6000*4200mm | 76kw | 7500kg | |

| 400-500kg/h | 16000*8000*4200mm | 95kw | 8500kg | |

| 500-700kg/h | 21000*9000*4200mm | 140kw | 10000kg | |

| 800-1000kg/h | 24000*10000*4500mm | 250kw | 14000kg | |

| 1500-2000kg/h | 28000*20000*5000mm | 470kw | 19000kg |

Main Characteristics:

1. Good comprehensive performance, high working efficiency(100-2000kg/h) and separation rate(99% separation rate).

2. High automatic program(PLC control system), reduce the human input, improve economic benefit.

3. Pulse and cyclone precipitator, dry type physical separation method(no fire, water, or chemical solution), no pollution in the whole process.

4. Reasonable structure, easy operation(only 1 or 2 workers need) and maintenance.

Customer Case:

Project cases

Project cases

Test and Inspection:

Before delivery, all of our machines will imitate the real production environment, use the customer need to deal with material test, to ensure the machine's performance and production to meet the customer requirements. We sincerely invite customers came to the scene for final test.

Leave Message

Please kindly leave your requirements in detail, or contact us via +86 15037138562. Our professional sales manager will contact you within 24 hours. Your contact information will be protected.

- QWhat machine do you want to learn about?

- Solar Panel Recycling Machine

- Lithium Battery Recycling Machine

- E-waste PCB Recycling Machine

- Copper Wire Recycling Machine

- Carbonization Pyrolysis Machine

- Radiator Recycling Machine

- Aluminum Plastic Recycling Machine

- Other:

- QWhat raw material do you want to process?

- Bamboo

- Wood

- Sawdust

- Coconut shell

- Palm Kernel Shell

- Wood Chips

- Not decided yet

- Other:

- QMachine processing capacity (tons of feedstock)

- Other:

- Not decided yet

- QWhat final product do you mainly want to obtain? For what applications?