Waste pcb board recycling machine

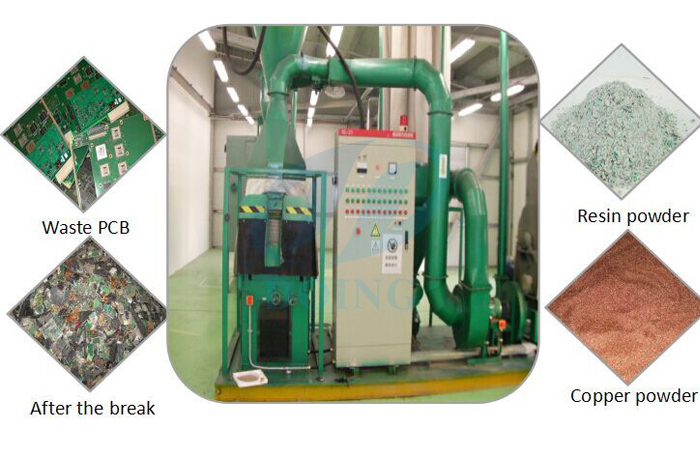

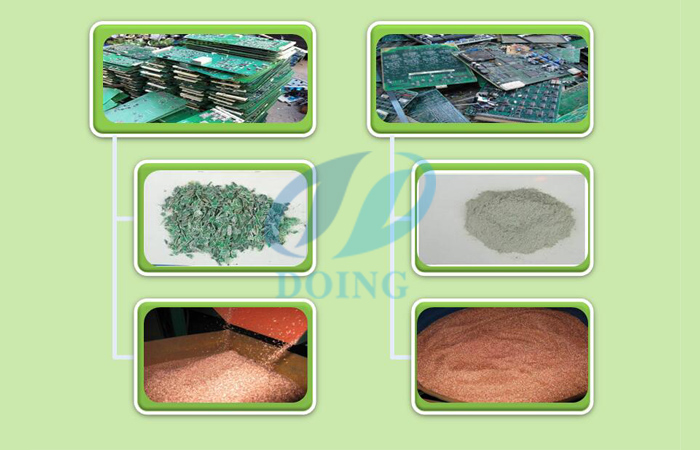

Our Waste PCB board recycling machine working principle is: Two times mechanical pulverization makes PCB into the mixtures of metal and nonmetal powder. Through the air separation technology, realizing the metal and nonmetal complete separation and collection. The whole process can be realized in one production line, fully closed operation ensures not creating any pollution.

Waste pcb board recycling machine

Waste pcb board recycling machine feature

PCB board recycling machine

1, compact structure, reasonable layout, stable performance, low noise.

2, PLC control complete production lines evenly feed, coordinated operation.

3, three-stage crushing, the processing capacity per hour 1200kg.

4, the grinding chamber by circulating water temperature control and noise reduction.

5, a full production line using vacuum feed effectively reduce dust overflow.

6, back to the material system the grinding more efficient.

7, air separation equipment sorting rate of 97 to 99%

8, pulse dust equipment efficiency as high as 99.99%.

9, high-voltage electrostatic separator make sorting more sophisticated and more efficient, effective control of non-ferrous metal loss.

10, full production line bridge and guardrail height settings, easy maintenance personnel of the equipment for real-time monitoring and maintenance.

Leave Message

Please kindly leave your requirements in detail, or contact us via +86 15037138562. Our professional sales manager will contact you within 24 hours. Your contact information will be protected.

- QWhat machine do you want to learn about?

- Solar Panel Recycling Machine

- Lithium Battery Recycling Machine

- E-waste PCB Recycling Machine

- Copper Wire Recycling Machine

- Carbonization Pyrolysis Machine

- Radiator Recycling Machine

- Aluminum Plastic Recycling Machine

- Other:

- QWhat raw material do you want to process?

- Bamboo

- Wood

- Sawdust

- Coconut shell

- Palm Kernel Shell

- Wood Chips

- Not decided yet

- Other:

- QMachine processing capacity (tons of feedstock)

- Other:

- Not decided yet

- QWhat final product do you mainly want to obtain? For what applications?