Waste pcb board recycling plant is mainly used for the separation of metal from non-metal in all kinds of waste circuit boards and other materials. Besides, it can destroy the data on the circuit boards.

Waste pcb board recycling plant

Waste pcb board recycling plant

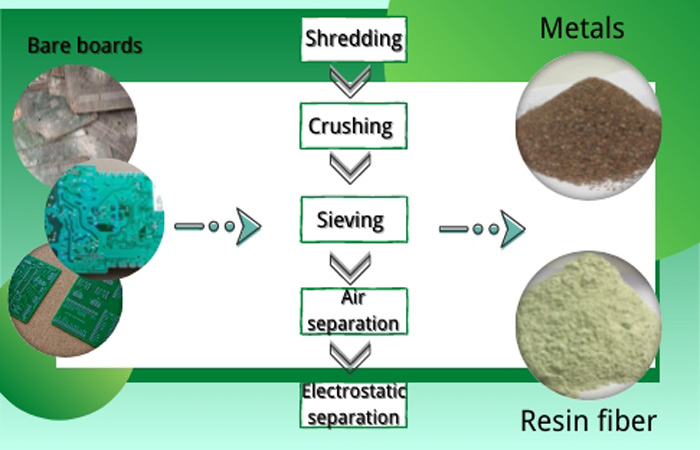

Working principle of waste pcb board recycling plant:

Waste pcb board recycling plant adopts recovery process of physical method, takes dry type crushing and separating all kinds of waste circuit boards, like computer mother boards, printed circuit boards, mobile phone boards, TV boards, refrigerator boards, copper clad laminate, etc. Its principle is mainly to crush the waste circuit boards into small particles and use air separator and electrostatic separator to separate metals from non-metals according to their different gravity and conductivity.

Specific processing flow of waste pcb board recycling plant:

Waste pcb boards - Shredding - Hammerhead crushing - Iron removal - Hammer crushing - Sieving - Air separation - Electrostatic separator - Dust removal

Working process of waste pcb board recycling plant

Working process of waste pcb board recycling plant

1. Send the waste circuit boards into shredder through a belt conveyor;

2. The double-shaft shredder will shred the complete waste circuit boards into small pieces about 3-4cm;

3. Use hammerhead crusher and hammer crush to pulverize the small pieces into a mixture with a particle size of about 2.5 mm; between the two crushing, a magnetic separator will be used to remove the iron.

4. In order to make sure the size of the particles, an eddy-vibrating screen will be used to control the size; the bigger particles will be sent back to hammer crusher for further crushing; and the enough small particles will pass through the next step;

5. Separate the metals and non-metals according to their different gravity and conductivity by using air separator and electrostatic separator;

6. Collect the dust by pulse dust collector and cyclone dust collector.

The above is the working video of waste pcb board recycling plant, which can help you have a better understanding of working process.

Final materials application of waste pcb board recycling plant:

Metals:

1). The separated metals has high purity and good quality, which can be sold directly to the metal trading market;

2). The metals are usually copper, gold, silver, tin, palladium, chrome and other rare elements, which can be purified and sold;

3). Since 90% of the mixed metal is copper, it can also be sold to copper smelters.

Final materials application

Final materials application

Non-metals:

1). The non-metals are resin fiber, which can be sold directly, but with low price;

2). Further processing and re-sale: grind to 80 mesh to make filler of resin tile and building brick; grind to 120 mesh to make ground paint; grind to 300 mesh to make heat insulation material and fireproof material.

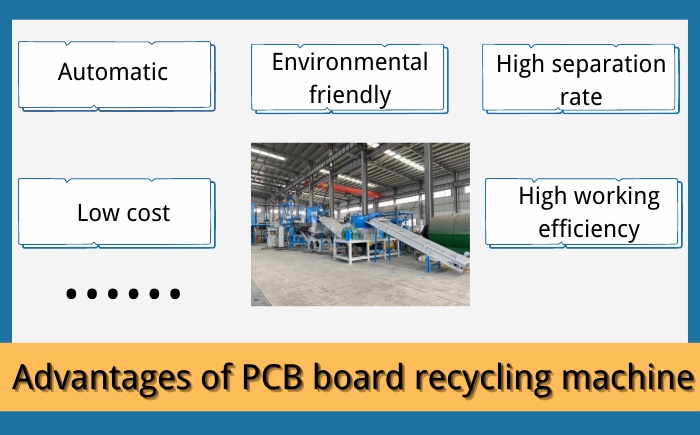

Characters of waste pcb board recycling plant:

1). High working efficiency: The largest capacity of waste pcb board recycling plant can deal with 2 ton waste circuit boards per hour. And if you have larger capacity needs, we can customize proper machine according to your needs.

2). Eco-friendly: Dry type physical separation method and dust collector prevent any pollution, such as water pollution, air pollution, to the environment. And the operating sound is below 85 decibels, which meets the standards of national industrial parks and will not cause noise pollution.

Characters of waste pcb board recycling plant

Characters of waste pcb board recycling plant

3). High degree of automation: It needs a few manual operation, due to it is equipped with PLC control system, which saves labor cost.

4). High sorting rate: Dual sorting process: Air separation and electrostatic separation makes the separating rate up to 99%, which can bring high profit.

Successfully project cases of waste pcb board recycling plant:

Henan Doing's waste pcb board recycling plant adopts advanced technology at home and abroad, and our plant takes the high voltage electrostatic separator with high purity metal recycling rate 98%. Besides, we also have many patent of electrostatic separator, pulse dust collector, etc. Welcome to choose Henan Doing, to get your reliable waste pcb board recycling plant.

Leave Message

Please kindly leave your requirements in detail, or contact us via +86 15037138562. Our professional sales manager will contact you within 24 hours. Your contact information will be protected.

- QWhat machine do you want to learn about?

- Solar Panel Recycling Machine

- Lithium Battery Recycling Machine

- E-waste PCB Recycling Machine

- Copper Wire Recycling Machine

- Carbonization Pyrolysis Machine

- Radiator Recycling Machine

- Aluminum Plastic Recycling Machine

- Other:

- QWhat raw material do you want to process?

- Bamboo

- Wood

- Sawdust

- Coconut shell

- Palm Kernel Shell

- Wood Chips

- Not decided yet

- Other:

- QMachine processing capacity (tons of feedstock)

- Other:

- Not decided yet

- QWhat final product do you mainly want to obtain? For what applications?