Waste PCB board recycling equipment, which is also called PCB recycling machine, is mainly used for separating precious metal and non-metal from the following materials, such as waste printed circuit boards, copper clad laminate, computer motherboards, cell phone boards, circuit boards and scraps, etc.

For waste PCB boards processing, there are two recycling ways:

1. Dismantling the electronic components

PCB dismantling machine

PCB dismantling machine

Firstly, dismantle the electronic components from waste PCB boards by PCB dismantling machine, then recycle the components and bare boards separately. For some valuable components such as CPUs, RAMs, memory chips, you can further extract gold/silver or other precious metals and then sell them for cash. As for the bare boards, you can use waste PCB board recycling equipment to separate mixed metals and resin fiber from them. The metal recycled from waste PCB boards can be used as a raw material for the metallurgical industry, and the resin fiber can be used as a raw material or a filler, which can bring high profit to us.

2. Processing waste PCB boards directly

Waste PCB board recycling equipment

Waste PCB board recycling equipment

Waste PCB board recycling equipment can recycle metals and resin fiber from waste PCB boards directly through shredding, crushing, sieving, air separation and electrostatic separation. After processing, the separated metal and non-metal can be sold directly for reuse. For without dismantling electronic components, the price of directly separated metals will be a little lower than after dismantling. But the data in waste PCB boards will be destroyed, which can protect our privacy.

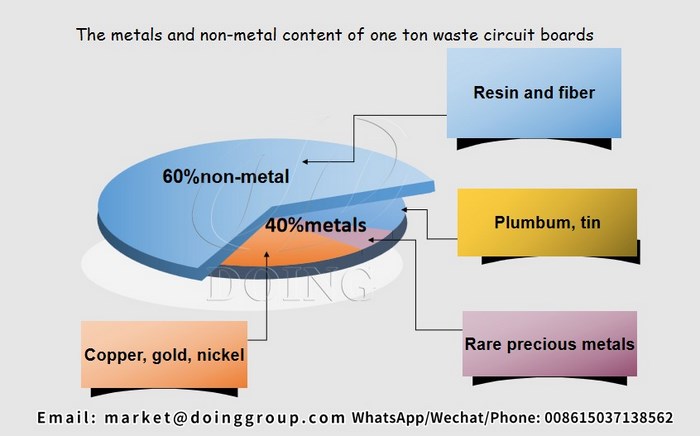

Metal and non-metal in waste PCB boards

Metal and non-metal in waste PCB boards

The circuit board usually contains 30% plastic, 30% inert oxide and 40% metal. The metal contains about 20% copper, 8% iron, 2% nickel, 4% tin, 2% zinc, and about 0.1% gold, 0.2% silver, 0.005% palladium. Among them, the price of copper is around $6840 per ton, the price of iron is around $106.01 per ton, and scrap metal fiberglass and resin powder can also be sold for additives and filling materials, and the profits are considerable.

Henan Doing Company waste PCB board recycling equipment has the following advantages:

1. Dry type physical separation method, no pollution.

2. PLC-controlled automated production line, high degree of automation.

3. Equipped with electrostatic separator, separation rate can reach to 99%.

4. High working efficiency, 100-2000kg/h processing capacity, or customization supported.

5. The whole production line adopts negative pressure feeding closed to effectively reduce dust overflow.

Waste PCB board recycling equipment

Waste PCB board recycling equipment

Waste PCB board recycling equipment has already become a leader in the e-waste recycling industry, and has a considerable investment prospects. Hurry up to contact us to get one set waste PCB board recycling equipment.

Leave Message

Please kindly leave your requirements in detail, or contact us via +86 15037138562. Our professional sales manager will contact you within 24 hours. Your contact information will be protected.

- QWhat machine do you want to learn about?

- Solar Panel Recycling Machine

- Lithium Battery Recycling Machine

- E-waste PCB Recycling Machine

- Copper Wire Recycling Machine

- Carbonization Pyrolysis Machine

- Radiator Recycling Machine

- Aluminum Plastic Recycling Machine

- Other:

- QWhat raw material do you want to process?

- Bamboo

- Wood

- Sawdust

- Coconut shell

- Palm Kernel Shell

- Wood Chips

- Not decided yet

- Other:

- QMachine processing capacity (tons of feedstock)

- Other:

- Not decided yet

- QWhat final product do you mainly want to obtain? For what applications?