3D video of aluminum plastic separation recycling machine running process

Editor: Henan Doing

This 3D video is designed by our engineers, which shows the whole running process of DOING aluminum plastic separation recycling machine. If you want to recycle waste medical blister, aluminum-plastic foil and aluminum-plastic panels to get separated pure aluminum and plastic, you can watch this video to learn more about it.

Aluminum plastic separation recycling machine

Aluminum plastic separation recycling machine

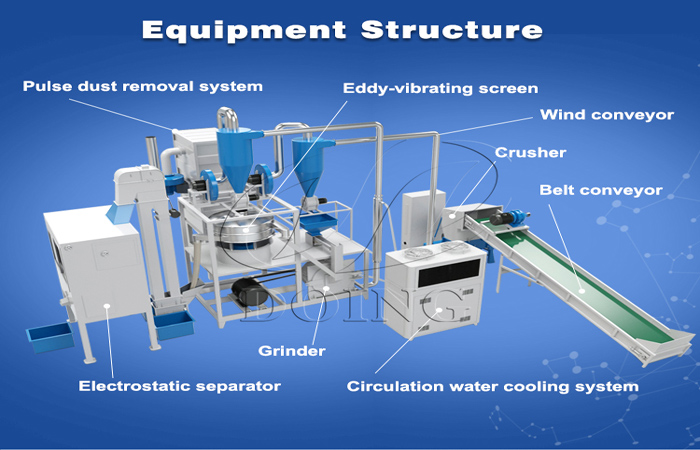

The raw material in this video is waste medical blister. The 3D video shows a simple configuration of an aluminum plastic separation recycling production line with a processing capacity of 300kg/h, which mainly includes a feeding conveyor belt, crusher, grinder, electromagnetic feeder, eddy-vibrating screen, electrostatic separator and dust removal system.

Structure of aluminum plastic separation recycling machine

Structure of aluminum plastic separation recycling machine

Taking into account the different needs of customers, we have different processing capacity and configurations of aluminum plastic separation recycling machine for choosing. While there will be differences in configuration and capacity, the basic principles are the same.

The detailed process is as follows:

1. Crushing

The first step is crushing, and the size of the broken materials after crushing is normally about 1cm. The crushed materials are conveyed to the next step through wind transport conveyor.

The wind transport conveyor is a fully enclosed transport, which can prevent the pollution of the factory working environment caused by flying materials and keep the environment around the machine clean. Moreover, when the air transport system is used to load materials under negative pressure, there will be no material jamming.

2. Grinding

The crushed material will be grind into powder for easier sorting. The crushed materials enter the electromagnetic feeder, which can control the feeding speed so that the materials enter the grinder evenly.

Grinder

Grinder

3. Circulation water cooling system

The grinder is equipped with a circulating water cooling system, which can reduce the plastic melting caused by the high temperature generated during the grinding process.

4. Eddy-vibrating screen

The eddy-vibrating screen is mainly used to control the particle size of ground materials. Larger materials will be fed back to the grinder for further grinding. Only materials of suitable size can be sorted.

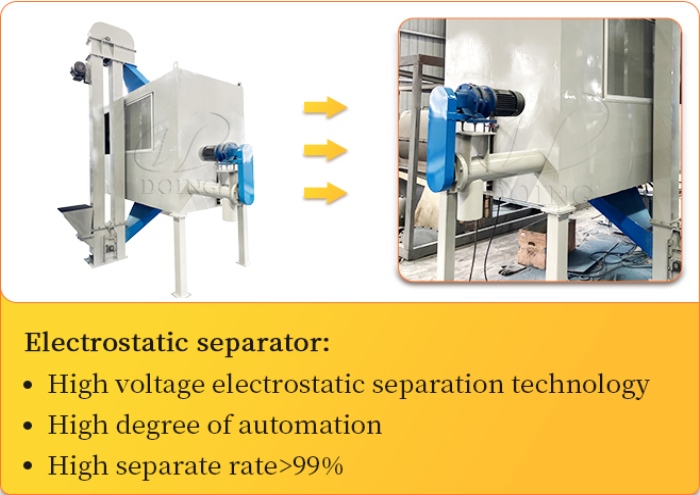

5. Electrostatic separator

Materials of proper sizes enter the electrostatic separator through the bucket elevator. The electrostatic separator uses the different electrification properties of metals and non-metals to separate aluminum and plastics. After sorting, the purity of aluminum and plastic is as high as 99.9%, and it can even be sold directly.

Electrostatic separator

Electrostatic separator

6. Dust removal system

During the whole process, we have an automatic dust removal system for dust removal.

The aluminum plastic separation recycling machine is compact in design and controlled by PLC control system, and just one or two worker for the entire operation. Saves both floor space and labor costs. Because of the high purity and quality of the separated aluminum and cost savings, DOING aluminum plastic separation recycling machine can bring you good profits. Here is a profit analysis chart that we made for your reference.

Profit analysis

Profit analysis

Since there are differences in the costs of raw materials, labor, electricity consumption, and the selling price of aluminum powers, you can make calculations based on your actual data.

Recycling waste aluminum-plastic products can be a valuable income stream if you are prepared to invest your time and effort. Our aluminum plastic separation recycling machines are specifically designed to assist you in achieving this objective, allowing you to maximize your profits. If you are interested and want to know more, please don't hesitate to contact us.

Leave Message

Please kindly leave your requirements in detail, or contact us via +86 15037138562. Our professional sales manager will contact you within 24 hours. Your contact information will be protected.

- QWhat machine do you want to learn about?

- Solar Panel Recycling Machine

- Lithium Battery Recycling Machine

- E-waste PCB Recycling Machine

- Copper Wire Recycling Machine

- Carbonization Pyrolysis Machine

- Radiator Recycling Machine

- Aluminum Plastic Recycling Machine

- Other:

- QWhat raw material do you want to process?

- Bamboo

- Wood

- Sawdust

- Coconut shell

- Palm Kernel Shell

- Wood Chips

- Not decided yet

- Other:

- QMachine processing capacity (tons of feedstock)

- Other:

- Not decided yet

- QWhat final product do you mainly want to obtain? For what applications?