PCB seapration machine

Pcb separation machine is developed in combination with advanced domestic and foreign technology. The pcb separation machine adopts advanced recycling process by physical methods. Such crushers and high voltage electrostatic separation devices developed by the company are of strong innovation, and their process lines for resource recycling are advanced and reasonable.

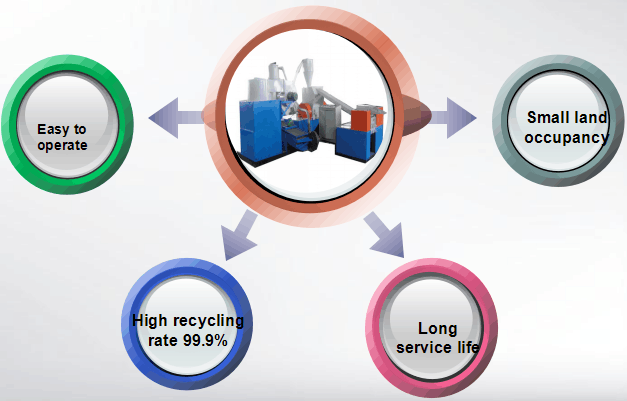

PCB seapration machine main feature

PCB seapration machine main feature

2.No need for water

3.Without dust polluction

4.High metal recovery rate

5.Saving motive power and human power

6.Without Wastes.

7.98% metal and nonmetal can be fully separated.

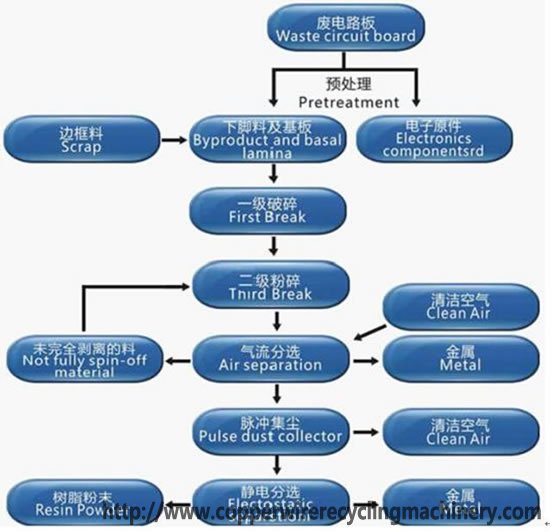

PCB seapration machine flow chart

PCB seapration machine working porcess

2:Use rough crusher to crush the PCB

3:Use minute crusher to crush the PCB again

4:Slurry will go to Vibrating table for first separating.

5:Vibrating table will separate the copper( including all metal) from plastics.

6:The slurry will go to another vibrating table for second separating to recover all metal.

7:Slurry will go to deposit pool

8:Water after deposit will go back to Minute crusher

PCB seapration machine advantage

(1) High recycling efficiency

(2) Good at solving problem of fibrous dust from kinds of circuit boards when pulverizing

(3) Eco-friendly

(4) Easy to operate and replace spare parts

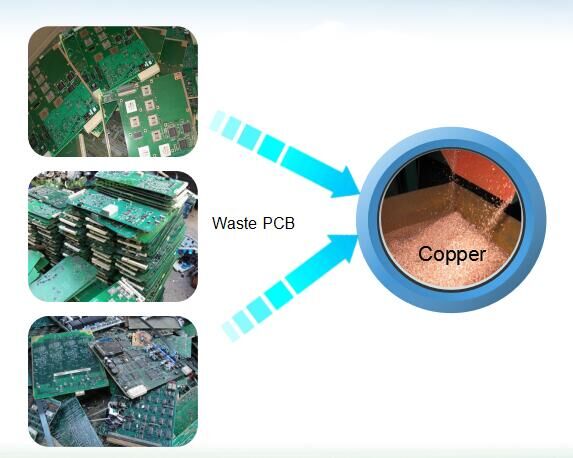

PCB seapration machine final product

PCB seapration machine final product

Leave Message

Please kindly leave your requirements in detail, or contact us via +86 15037138562. Our professional sales manager will contact you within 24 hours. Your contact information will be protected.

- QWhat machine do you want to learn about?

- Solar Panel Recycling Machine

- Lithium Battery Recycling Machine

- E-waste PCB Recycling Machine

- Copper Wire Recycling Machine

- Carbonization Pyrolysis Machine

- Radiator Recycling Machine

- Aluminum Plastic Recycling Machine

- Other:

- QWhat raw material do you want to process?

- Bamboo

- Wood

- Sawdust

- Coconut shell

- Palm Kernel Shell

- Wood Chips

- Not decided yet

- Other:

- QMachine processing capacity (tons of feedstock)

- Other:

- Not decided yet

- QWhat final product do you mainly want to obtain? For what applications?