Waste circuit boards recycling system is an entire recycling system, which includes two parts: electronic components dismantling machine and circuit board recycling machine. It is mainly used for processing various waste circuit boards, like printed circuit boards, computer motherboards, TV boards, mobile boards, copper clad laminate, etc. which are common in our daily life and easy to collect, to get mixed metals and resin fiber.

Electronic components dismantling machine

Electronic components dismantling machine

Electronic components dismantling machine is used to dismantle the electronic components from waste circuit boards. Because the electronic components and bare boards are connected by tin, whose has a lower melting point. When the electronic component dismantling machine heats and rotates, tin will be melted, the electronic components will be separated from the circuit boards due to the circuit boards rub against each other.

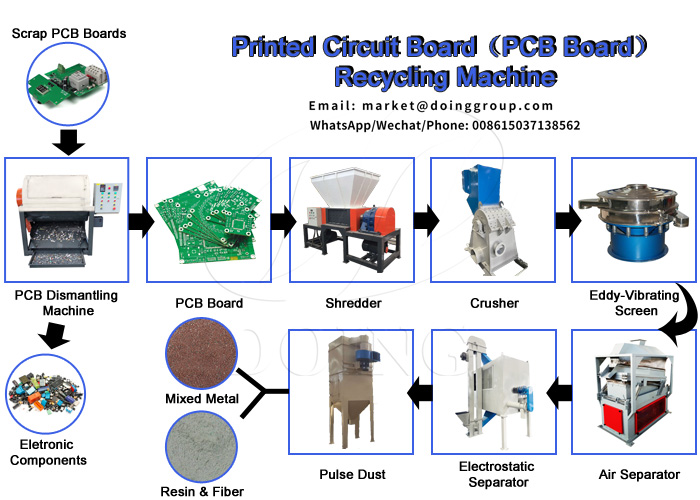

Working process of circuit board recycling machine

Working process of circuit board recycling machine

Then circuit board recycling machine will process the bare circuit boards. The whole working process is shred bare boards to 3-5cm pieces → first hammerhead crusher crush pieces into 1-2cm → magnetic separator separate iron out → second hammer crusher crush piecesinto 20-24 mesh particles → eddy-vibration screen sieving, the large particles will be sent back to crusher for further crushing, and the small particles will go to the next step → air separator separates resin fiber and most metals → electrostatic separator separates the rest metal from resin fiber → dust removal system.

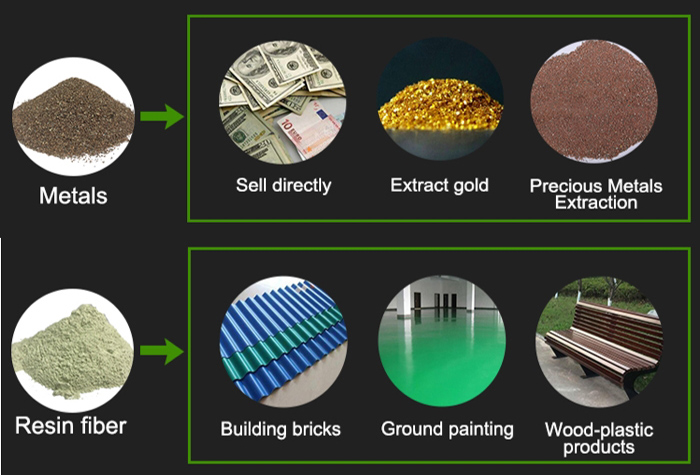

Final products' uses

Final products' uses

The separated mixed metals has 99% separation rate and good quality. They can be sold directly in the metal trading market at a pretty high price. As for the resin fiber, they also have wide application, like resin tiles, ground painting, wood-plastic products, etc. Both of them can bring high profit to us.

Waste circuit board recycling system

Waste circuit board recycling system

The conventional daily processing capacity of DOING waste circuit boards recycling system is 100-2000kg/h. If you have larger processing capacity needs, our engineer can customize the suitable solution and configuration for you. Welcome to contact us feel free.

Leave Message

Please kindly leave your requirements in detail, or contact us via +86 15037138562. Our professional sales manager will contact you within 24 hours. Your contact information will be protected.

- QWhat machine do you want to learn about?

- Solar Panel Recycling Machine

- Lithium Battery Recycling Machine

- E-waste PCB Recycling Machine

- Copper Wire Recycling Machine

- Carbonization Pyrolysis Machine

- Radiator Recycling Machine

- Aluminum Plastic Recycling Machine

- Other:

- QWhat raw material do you want to process?

- Bamboo

- Wood

- Sawdust

- Coconut shell

- Palm Kernel Shell

- Wood Chips

- Not decided yet

- Other:

- QMachine processing capacity (tons of feedstock)

- Other:

- Not decided yet

- QWhat final product do you mainly want to obtain? For what applications?